Understanding the Role of Vibrating Screen Exciters in Material Processing

Nov 02,2025

In the manufacturing and processing machinery sector, particularly in the field of crushing and sorting equipment, vibrating screen exciters play a pivotal role. These devices are integral to the operation of vibrating screens, which are commonly used for separating materials based on size. Understanding how vibrating screen exciters work and their significance can provide valuable insights for professionals in the industry.

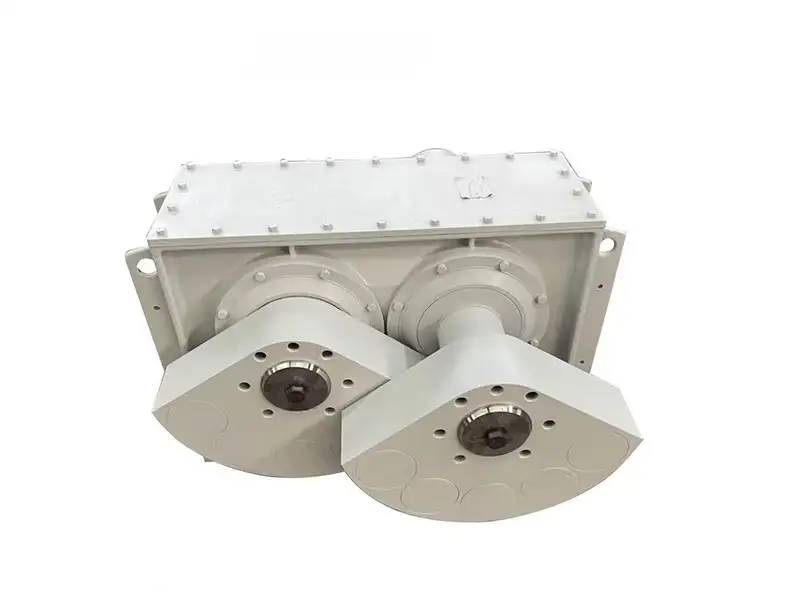

A vibrating screen exciter is a mechanical device that generates vibration in a vibrating screen. This vibration is crucial for the effective separation of materials, allowing finer particles to pass through while coarser materials are retained. The exciter typically consists of two eccentric shafts that rotate in opposite directions, creating a dynamic motion that ensures efficient screening. This dual rotation helps maintain the balance of the screen, minimizing wear and tear and prolonging the lifespan of the equipment.

One of the primary advantages of employing vibrating screen exciters is their ability to enhance material handling efficiency. By optimizing the vibration frequency and amplitude, operators can adjust the screening process to suit various material types and sizes. This adaptability is particularly beneficial in applications where materials vary significantly, enabling more precise sorting and reducing the likelihood of clogging or material build-up.

Moreover, vibrating screen exciters contribute significantly to the overall productivity of sorting and screening operations. The consistent and reliable vibration they produce ensures that materials are processed uniformly, which can lead to higher throughput rates. This efficiency is vital in industries such as mining, recycling, and aggregate production, where time and resource management are critical.

In addition to their operational benefits, vibrating screen exciters also play a role in improving workplace safety. By effectively separating materials, they help prevent the accumulation of potentially hazardous substances, reducing the risk of accidents or equipment failures. Operators can work more confidently knowing that their equipment is functioning optimally, leading to a safer working environment.

Maintenance of vibrating screen exciters is crucial for ensuring long-term performance. Regular inspections and timely replacements of worn components can prevent unexpected downtime and costly repairs. Additionally, understanding the specific needs of the exciter based on the materials processed can aid in selecting the right specifications for enhanced performance.

In summary, vibrating screen exciters are critical components in the manufacturing and processing machinery industry, specifically within crushing and sorting equipment. Their ability to generate vibration facilitates effective material separation, enhances productivity, and promotes workplace safety. For professionals in the field, a comprehensive understanding of vibrating screen exciters is essential for optimizing operations and achieving better results.

A vibrating screen exciter is a mechanical device that generates vibration in a vibrating screen. This vibration is crucial for the effective separation of materials, allowing finer particles to pass through while coarser materials are retained. The exciter typically consists of two eccentric shafts that rotate in opposite directions, creating a dynamic motion that ensures efficient screening. This dual rotation helps maintain the balance of the screen, minimizing wear and tear and prolonging the lifespan of the equipment.

One of the primary advantages of employing vibrating screen exciters is their ability to enhance material handling efficiency. By optimizing the vibration frequency and amplitude, operators can adjust the screening process to suit various material types and sizes. This adaptability is particularly beneficial in applications where materials vary significantly, enabling more precise sorting and reducing the likelihood of clogging or material build-up.

Moreover, vibrating screen exciters contribute significantly to the overall productivity of sorting and screening operations. The consistent and reliable vibration they produce ensures that materials are processed uniformly, which can lead to higher throughput rates. This efficiency is vital in industries such as mining, recycling, and aggregate production, where time and resource management are critical.

In addition to their operational benefits, vibrating screen exciters also play a role in improving workplace safety. By effectively separating materials, they help prevent the accumulation of potentially hazardous substances, reducing the risk of accidents or equipment failures. Operators can work more confidently knowing that their equipment is functioning optimally, leading to a safer working environment.

Maintenance of vibrating screen exciters is crucial for ensuring long-term performance. Regular inspections and timely replacements of worn components can prevent unexpected downtime and costly repairs. Additionally, understanding the specific needs of the exciter based on the materials processed can aid in selecting the right specifications for enhanced performance.

In summary, vibrating screen exciters are critical components in the manufacturing and processing machinery industry, specifically within crushing and sorting equipment. Their ability to generate vibration facilitates effective material separation, enhances productivity, and promotes workplace safety. For professionals in the field, a comprehensive understanding of vibrating screen exciters is essential for optimizing operations and achieving better results.

PREVIOUS: