Understanding Vibrating Motors: Applications and Functionality

Nov 20,2025

Vibrating motors are specialized devices designed to generate mechanical vibrations. These motors are unique because they convert electrical energy into kinetic energy through the action of vibration. They play an essential role in numerous applications across different industries, particularly in the realm of electrical and electronic engineering.

At the core of a vibrating motor lies an eccentric mass, which is attached to the rotor. When the motor is powered, this eccentric mass causes the motor to vibrate, creating movement that can be utilized in various applications. The frequency and amplitude of these vibrations can be adjusted, allowing for a wide range of functionalities based on the requirements of a specific task.

One primary application of vibrating motors is in material handling systems. They are used to facilitate the movement of bulk materials, such as grains, powders, and aggregates. In this context, they help prevent blockages in chutes and hoppers, ensuring a constant flow of materials. This application is particularly common in the food processing and construction industries, where efficient material transport is crucial.

Additionally, vibrating motors are widely utilized in the manufacturing sector, especially in automated assembly lines. They can assist in parts sorting, orienting, and feeding, thus improving the efficiency and speed of production processes. The vibrations help to separate and position items accurately, which is critical in achieving high levels of automation and productivity.

Another significant application of vibrating motors is in consumer electronics. They are commonly found in mobile devices, providing haptic feedback to users. This feedback enhances the user experience by giving tactile responses during notifications or interactions, such as typing on a touchscreen.

Moreover, vibrating motors have applications in the medical field, where they are used in devices such as therapeutic equipment and massage chairs. The vibrations can promote relaxation and relieve muscle tension, contributing to overall wellness.

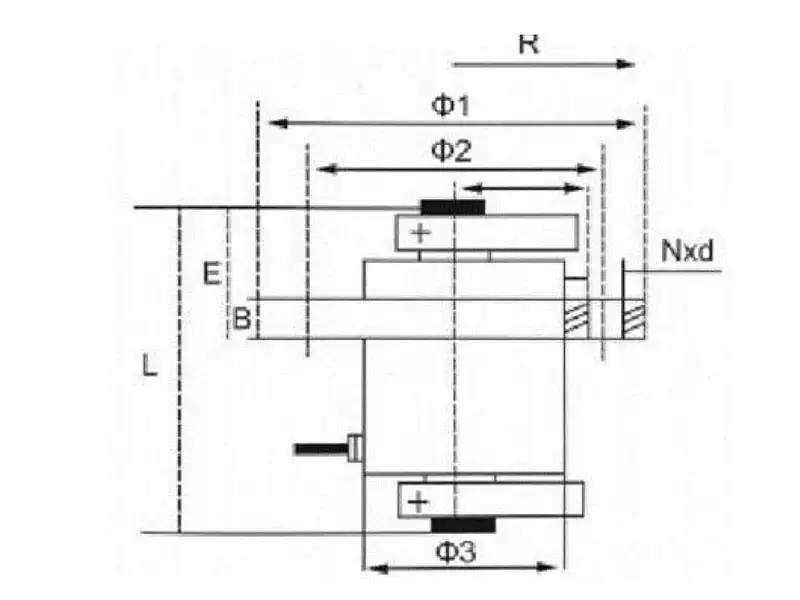

When selecting a vibrating motor, professionals should consider various factors, including motor type, size, power requirements, and vibration frequency. Understanding the specific needs of the application will ensure optimal performance and efficiency.

In conclusion, vibrating motors are versatile components that play a vital role in numerous industries. Their ability to convert electrical energy into mechanical vibrations allows for innovative solutions in material handling, manufacturing, consumer electronics, and more. For professionals in the electric and electronic sectors, gaining a comprehensive understanding of vibrating motors is essential to leverage their potential in enhancing operational efficiency and product quality.

At the core of a vibrating motor lies an eccentric mass, which is attached to the rotor. When the motor is powered, this eccentric mass causes the motor to vibrate, creating movement that can be utilized in various applications. The frequency and amplitude of these vibrations can be adjusted, allowing for a wide range of functionalities based on the requirements of a specific task.

One primary application of vibrating motors is in material handling systems. They are used to facilitate the movement of bulk materials, such as grains, powders, and aggregates. In this context, they help prevent blockages in chutes and hoppers, ensuring a constant flow of materials. This application is particularly common in the food processing and construction industries, where efficient material transport is crucial.

Additionally, vibrating motors are widely utilized in the manufacturing sector, especially in automated assembly lines. They can assist in parts sorting, orienting, and feeding, thus improving the efficiency and speed of production processes. The vibrations help to separate and position items accurately, which is critical in achieving high levels of automation and productivity.

Another significant application of vibrating motors is in consumer electronics. They are commonly found in mobile devices, providing haptic feedback to users. This feedback enhances the user experience by giving tactile responses during notifications or interactions, such as typing on a touchscreen.

Moreover, vibrating motors have applications in the medical field, where they are used in devices such as therapeutic equipment and massage chairs. The vibrations can promote relaxation and relieve muscle tension, contributing to overall wellness.

When selecting a vibrating motor, professionals should consider various factors, including motor type, size, power requirements, and vibration frequency. Understanding the specific needs of the application will ensure optimal performance and efficiency.

In conclusion, vibrating motors are versatile components that play a vital role in numerous industries. Their ability to convert electrical energy into mechanical vibrations allows for innovative solutions in material handling, manufacturing, consumer electronics, and more. For professionals in the electric and electronic sectors, gaining a comprehensive understanding of vibrating motors is essential to leverage their potential in enhancing operational efficiency and product quality.

PREVIOUS: