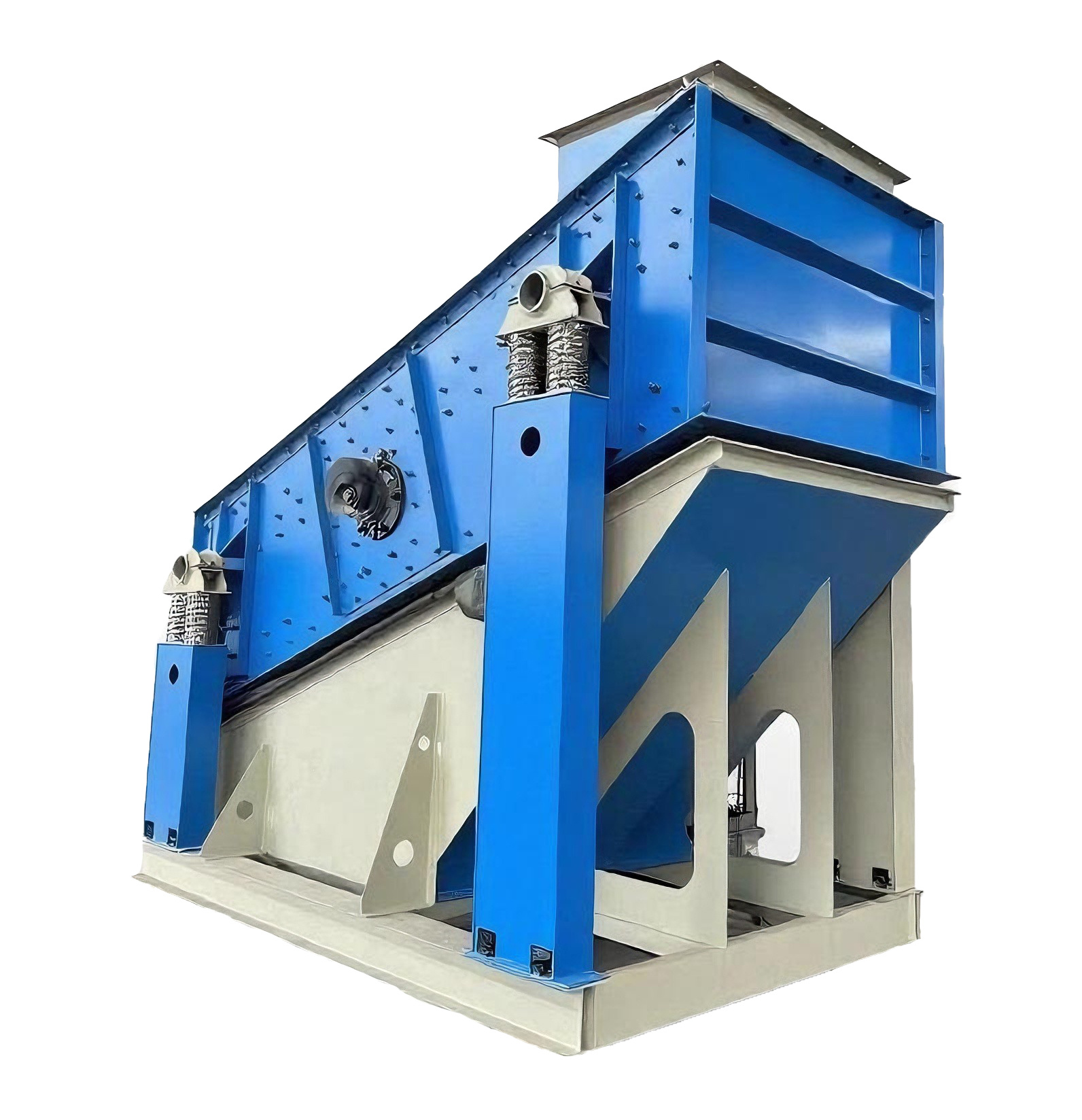

"Successful Delivery of Semi-Sealed Circular Vibrating Screen with Material Bin: A New Era of Efficient Production Begins"

Aug 15,2025

A batch of highly anticipated semi-sealed circular vibrating screens with material bins was successfully dispatched from Xinxiang and is about to be sent to the customer's site to be put into intense production operations.

Semi-sealed circular vibrating screens with silos play a significant role in industrial production. The circular vibrating screen part of this equipment adopts advanced technology, with precise vibration trajectories, capable of efficiently screening and grading various materials. Whether it is ore screening in mining, sand and gravel separation in the building materials industry, or raw material processing in the chemical field, it can all demonstrate outstanding screening effects. Its semi-sealed design is a major highlight, effectively reducing the dust flying during the screening process of materials. This not only ensures a clean production environment but also reduces material loss, meeting the dual demands of environmental protection and efficient production.

The design with a material bin greatly enhances the practicality of the equipment. The silo has a certain material storage capacity and can achieve continuous and stable feeding, reducing the cumbersome operation of frequent manual feeding and greatly improving production efficiency. Meanwhile, through the precise feeding control device, the feeding amount can be flexibly adjusted according to production demands, ensuring the smoothness and efficiency of the screening process.

It is understood that the equipment orders for this shipment come from enterprises in multiple industries. After conducting research and comparison on numerous similar devices in the market, these enterprises ultimately chose this semi-sealed circular vibrating screen with a material bin. What we value is the comprehensive performance of this device and the good reputation of the manufacturer. A purchasing manager from a building materials enterprise said, "It not only meets our current requirements for output and screening accuracy, but also its environmentally friendly design makes us more at ease when dealing with increasingly strict environmental protection standards."

A relevant person in charge of the equipment manufacturer introduced that in order to ensure the timely and high-quality delivery of this batch of equipment, the company's production department has been working overtime and strictly controlling every production link. From raw material procurement to component processing, and then to the assembly and commissioning of the equipment, all follow a high-standard quality control system. Before shipment, each piece of equipment was subject to a comprehensive and meticulous inspection to ensure that it could be put into use promptly upon arrival at the customer's site, creating value for the customer.

With the smooth delivery of this batch of equipment, they will play a significant role on the production line, helping enterprises enhance production efficiency, reduce production costs, and promote the high-quality development of the industry. In the future, equipment manufacturers will also continue to increase investment in research and development, constantly optimize product performance, and bring more high-quality and efficient industrial equipment to the market.

PREVIOUS: