Top Features to Look for in Hanging Vibrating Feeders for Facilities Agriculture

Oct 17,2025

Top Features to Look for in Hanging Vibrating Feeders for Facilities Agriculture

Introduction to Hanging Vibrating Feeders

In the fast-evolving world of agriculture, especially in facilities agriculture, the demand for efficient feeding systems has skyrocketed. Hanging vibrating feeders have emerged as a revolutionary solution for delivering feed to livestock and crops. These devices ensure a steady and controlled flow of feed, minimizing waste and maximizing productivity. In this comprehensive guide, we will delve into the key features to consider when selecting the ideal hanging vibrating feeder for your agricultural facility.

Understanding the Importance of Hanging Vibrating Feeders

Hanging vibrating feeders play a crucial role in modern agricultural practices. They are designed to transport bulk materials efficiently, making them invaluable in settings where consistency and speed are paramount. By analyzing feed characteristics and operational environments, we can appreciate how these feeders contribute to the overall success of agricultural operations.

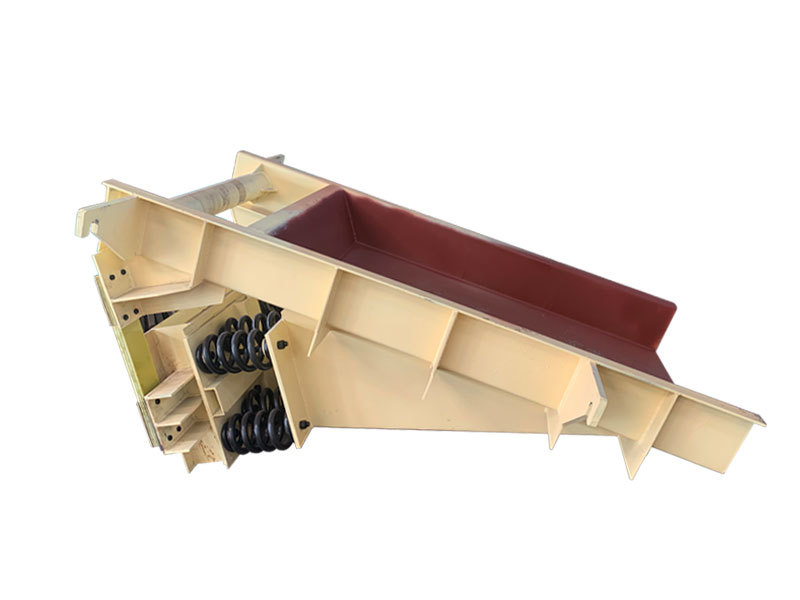

The Mechanism Behind Hanging Vibrating Feeders

Hanging vibrating feeders operate on the principle of vibration, which allows for the smooth transition of materials from one location to another. This mechanism ensures that feed is dispensed uniformly, preventing clumping or blockage, which can hamper efficiency. Understanding how these feeders function is essential for recognizing their benefits in facilities agriculture.

Key Features to Consider in Hanging Vibrating Feeders

1. Durability and Material Quality

When investing in hanging vibrating feeders, the durability of the materials used is non-negotiable. Look for feeders constructed from high-quality, corrosion-resistant materials such as stainless steel or reinforced plastics. These materials withstand harsh environmental conditions, ensuring a long lifespan and consistent performance.

Corrosion Resistance

Corrosion can significantly impact the performance of feeders, especially in humid or chemically active environments. Opt for feeders that feature protective coatings or are made from alloys that resist corrosion to minimize maintenance and replacements.

2. Adjustable Feed Rate

The ability to adjust the feed rate is a crucial feature of hanging vibrating feeders. This functionality allows operators to customize the flow of feed based on the specific needs of their livestock or crops. Look for models that offer easy-to-use controls, enabling quick adjustments without extensive downtime.

Benefits of Variable Feed Rates

A variable feed rate helps to optimize feed consumption, ensuring that animals receive the right amount of nutrients. This not only improves health outcomes but also enhances overall productivity in agricultural settings.

3. Vibration Control Mechanisms

Efficient vibration control is a defining feature of high-quality hanging vibrating feeders. Opt for devices that offer precise vibration settings to ensure the smooth movement of feed. Advanced models may include features like adjustable amplitude and frequency, allowing for tailored performance.

Impact on Feed Uniformity

A well-controlled vibration mechanism contributes to uniform feed distribution, reducing waste and ensuring that all animals or crops receive the necessary nutrients evenly.

4. Size and Capacity

The size and capacity of the feeder are fundamental considerations. Assess the scale of your agricultural operation and choose a feeder that meets your specific needs. Larger facilities may require feeders with higher capacities to keep up with demand, while smaller operations may benefit from more compact models.

Space Optimization

Select a feeder that fits well within your facility's layout. Space-efficient designs can help maximize operational areas, contributing to a more organized and efficient working environment.

5. Ease of Installation and Maintenance

User-friendly installation and maintenance processes are crucial for reducing operational disruptions. Choose feeders that come with clear installation instructions and require minimal tools for setup. Additionally, maintenance should be straightforward, allowing for regular checks without heavy labor.

Long-term Maintenance Costs

Investing in feeders that are easy to maintain can lead to significant cost savings over time. Consider models with readily available replacement parts and support services to ensure continuity of operations.

6. Compatibility with Other Agricultural Equipment

To ensure seamless integration into your existing agricultural setup, choose hanging vibrating feeders that are compatible with other equipment. Whether it’s tractors, conveyor belts, or storage systems, compatibility can enhance efficiency and productivity.

Enhancing Workflow Efficiency

A compatible feeder can streamline processes, reducing the time and effort needed for feeding. This integration can significantly enhance overall workflow and productivity in agricultural operations.

7. Safety Features

Safety should always be a priority in agricultural settings. Look for hanging vibrating feeders that include safety features such as emergency shut-off switches, protective guards, and overload protection systems.

Protecting Workers and Equipment

Incorporating safety features not only protects your workers but also safeguards the equipment, reducing the risks of costly accidents and downtime.

8. Energy Efficiency

With energy costs on the rise, selecting an energy-efficient vibrating feeder is essential. Look for models designed to minimize energy consumption while delivering optimal performance.

Reducing Operating Costs

Energy-efficient feeders can significantly lower your operational costs, allowing you to allocate resources more effectively within your agricultural business.

Conclusion: Making the Right Choice

Selecting the right hanging vibrating feeder for facilities agriculture involves careful consideration of multiple features, from durability and feed rate adjustments to safety and energy efficiency. By prioritizing these elements, agricultural professionals can enhance productivity, improve animal health, and reduce operational costs. It's essential to choose a feeder that aligns with your specific needs and integrates seamlessly into your existing systems. Investing in high-quality, feature-rich hanging vibrating feeders will undoubtedly pay off in the long run, supporting the success and sustainability of your agricultural operations.

FAQs: Commonly Asked Questions

1. What is a hanging vibrating feeder?

A hanging vibrating feeder is a device used in agriculture to transport and dispense feed or bulk materials through controlled vibration, ensuring a steady flow without clumping or blocking.

2. How does a vibrating feeder improve feed efficiency?

By providing a controlled and adjustable feed rate, vibrating feeders ensure that animals receive the right amount of nutrients consistently, reducing waste and optimizing health outcomes.

3. Are hanging vibrating feeders easy to maintain?

Yes, many modern hanging vibrating feeders are designed for ease of maintenance, featuring accessible components and straightforward procedures to ensure minimal downtime.

4. What materials are best for hanging vibrating feeders?

High-quality materials, such as stainless steel or reinforced plastics, are ideal for durability and corrosion resistance, especially in challenging agricultural environments.

5. Can hanging vibrating feeders be integrated with other agricultural equipment?

Yes, compatibility with other equipment is crucial for enhancing workflow efficiency. Always check for compatibility specifications before purchasing a feeder.

By focusing on these features and considerations, agricultural professionals can make informed decisions that enhance their operations and ultimately lead to greater success in facilities agriculture.