Enhancing Material Flow Efficiency with Hanging Vibrating Feeders

Aug 04,2025

In modern industrial production lines, the demand for efficient, reliable, and space-saving material handling solutions is constantly growing. One such innovation that has significantly contributed to improved productivity and reduced operational costs is the Hanging Vibrating Feeder. This essential equipment has become a staple in industries such as mining, construction, metallurgy, and aggregates processing, providing a continuous, controlled flow of bulk materials in challenging environments.

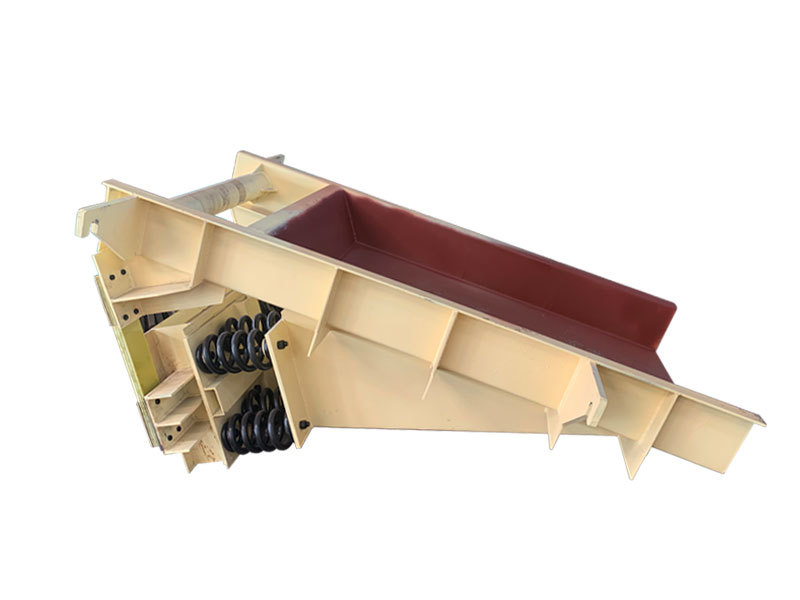

Hanging Vibrating Feeders are designed to be suspended from support structures, which makes them particularly advantageous in facilities with limited floor space or where ground-mounted equipment is impractical. These feeders utilize powerful vibratory motors or electromagnetic drives to generate consistent and controllable vibrations. The vibrations create a linear or elliptical motion that smoothly moves material along a trough or pan, delivering it to crushers, screens, conveyors, or storage bins without clogging, surging, or overflow.

One of the primary benefits of Hanging Vibrating Feeders is their ability to handle a wide range of materials, including fine powders, moist aggregates, abrasive minerals, and large, heavy rocks. The vibration intensity and feed rate can be easily adjusted to match the specific properties of the material and the requirements of downstream processes. This level of customization ensures optimal performance and minimal waste.

In the mining industry, Hanging Vibrating Feeders are often used in primary crushing stations to pre-screen and feed large quantities of ore or rock to jaw crushers. By doing so, they help eliminate fines and ensure that only appropriately sized material enters the crusher, improving the efficiency and lifespan of the equipment. In construction and aggregate applications, these feeders are used to transport sand, gravel, and crushed stone to processing units without causing blockages or material degradation.

Their versatility also extends to the recycling and cement industries, where they are used to handle mixed materials and provide steady flow for sorting, grinding, and blending operations. The robust construction of Hanging Vibrating Feeders, often made with wear-resistant steel and reinforced frames, allows them to operate continuously under high loads and harsh conditions. Advanced models may include sealed designs to minimize dust emission, adjustable counterweights for vibration tuning, and variable frequency drives for precise speed control.

Another significant advantage of this equipment is its low maintenance requirements. Since there are few moving parts and no belts or chains involved, the risk of mechanical failure is minimal. Routine inspections and occasional lubrication of bearings are usually sufficient to keep the system running efficiently for extended periods. This reliability translates into lower downtime, reduced labor costs, and increased overall productivity.

Moreover, the installation of Hanging Vibrating Feeders is relatively straightforward. With proper engineering design, they can be easily integrated into existing systems or included in new plant layouts. Their modularity and adaptability also make them suitable for portable and mobile crushing units, where space and weight constraints are crucial.

As industries continue to evolve toward more automated and energy-efficient systems, Hanging Vibrating Feeders have also adapted by incorporating smart features. Modern units can be equipped with sensors and control systems that monitor material flow, detect blockages, and adjust feed rates automatically. These intelligent systems contribute to safer operation, improved material handling, and better integration with the overall production management software.

In summary, Hanging Vibrating Feeders have proven to be a vital component in modern industrial operations where consistent material flow, space efficiency, and reliability are paramount. Their ability to handle diverse materials, adapt to different operational needs, and deliver continuous feeding with minimal maintenance makes them a preferred choice for engineers and plant managers worldwide. As technology continues to advance, the capabilities and efficiency of these feeders are expected to improve further, solidifying their role in the future of material processing and handling.