Understanding Small Jaw Crushers: A Comprehensive Guide for Efficient Crushing

Sep 26,2025

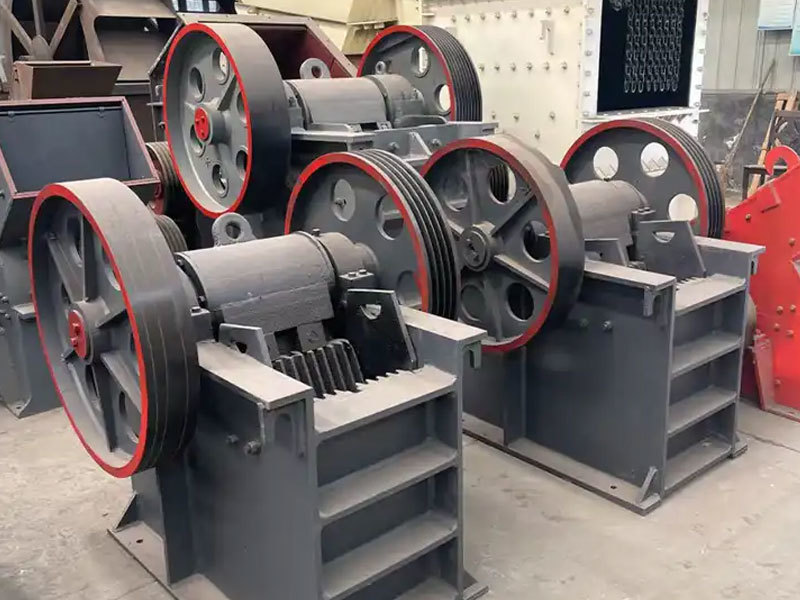

Small jaw crushers are essential tools in the world of manufacturing and processing machinery, particularly in the field of crushing and sorting. Designed to handle a variety of materials, these compact machines are known for their efficiency, versatility, and ability to produce high-quality output. This article provides an in-depth overview of small jaw crushers, highlighting their features, benefits, and common applications.

Small jaw crushers typically consist of two jaws—one fixed and the other movable—that work together to crush materials by applying pressure. When material enters the crushing chamber, the movable jaw approaches the fixed jaw, creating a narrowing space that generates enough pressure to fracture the material. This mechanism is not only effective but also allows for a consistent and controlled crushing process.

One of the primary benefits of small jaw crushers is their compact size. This makes them ideal for operations where space is limited. These machines can be easily integrated into existing production lines or used as standalone units. Additionally, their smaller footprint makes them cost-effective, allowing businesses to achieve high levels of productivity without the need for large-scale machinery investments.

Moreover, small jaw crushers are versatile and can handle a wide range of materials, including rocks, minerals, and even some types of industrial waste. This adaptability makes them suitable for various industries, including mining, construction, and recycling. In the mining sector, small jaw crushers are often utilized to process ores and aggregate materials, preparing them for transport and further processing. In recycling operations, these machines can help reduce waste by efficiently breaking down materials for reuse.

In terms of maintenance, small jaw crushers require relatively low upkeep compared to larger models. Routine inspections and proper lubrication can significantly extend the lifespan of these machines, ensuring they operate at peak efficiency. Additionally, many small jaw crushers are designed with user-friendly features, making them easier to operate and maintain, even for personnel with limited technical expertise.

When considering a small jaw crusher for your operations, it's essential to evaluate your specific needs. Factors such as the type of materials you will be processing, the desired output size, and the volume of material to be crushed should all influence your decision. By selecting the right small jaw crusher, businesses can enhance their productivity, reduce operational costs, and achieve greater efficiency in their crushing processes.

In summary, small jaw crushers play a crucial role in the field of manufacturing and processing machinery. Their compact design, versatility, and low maintenance requirements make them an excellent choice for a wide range of applications. By understanding the benefits and functionalities of these machines, businesses can make informed decisions that will optimize their operations and contribute to long-term success.

Small jaw crushers typically consist of two jaws—one fixed and the other movable—that work together to crush materials by applying pressure. When material enters the crushing chamber, the movable jaw approaches the fixed jaw, creating a narrowing space that generates enough pressure to fracture the material. This mechanism is not only effective but also allows for a consistent and controlled crushing process.

One of the primary benefits of small jaw crushers is their compact size. This makes them ideal for operations where space is limited. These machines can be easily integrated into existing production lines or used as standalone units. Additionally, their smaller footprint makes them cost-effective, allowing businesses to achieve high levels of productivity without the need for large-scale machinery investments.

Moreover, small jaw crushers are versatile and can handle a wide range of materials, including rocks, minerals, and even some types of industrial waste. This adaptability makes them suitable for various industries, including mining, construction, and recycling. In the mining sector, small jaw crushers are often utilized to process ores and aggregate materials, preparing them for transport and further processing. In recycling operations, these machines can help reduce waste by efficiently breaking down materials for reuse.

In terms of maintenance, small jaw crushers require relatively low upkeep compared to larger models. Routine inspections and proper lubrication can significantly extend the lifespan of these machines, ensuring they operate at peak efficiency. Additionally, many small jaw crushers are designed with user-friendly features, making them easier to operate and maintain, even for personnel with limited technical expertise.

When considering a small jaw crusher for your operations, it's essential to evaluate your specific needs. Factors such as the type of materials you will be processing, the desired output size, and the volume of material to be crushed should all influence your decision. By selecting the right small jaw crusher, businesses can enhance their productivity, reduce operational costs, and achieve greater efficiency in their crushing processes.

In summary, small jaw crushers play a crucial role in the field of manufacturing and processing machinery. Their compact design, versatility, and low maintenance requirements make them an excellent choice for a wide range of applications. By understanding the benefits and functionalities of these machines, businesses can make informed decisions that will optimize their operations and contribute to long-term success.

PREVIOUS: