The Importance of Jaw Crushers in the Recycling Industry: A Comprehensive Guide

Jan 19,2026

The Importance of Jaw Crushers in the Recycling Industry

Table of Contents

- 1. Introduction to Jaw Crushers and Recycling

- 2. Understanding Jaw Crushers

- 3. Types of Jaw Crushers in the Recycling Sector

- 4. Key Benefits of Jaw Crushers in Recycling

- 5. Applications of Jaw Crushers in the Recycling Industry

- 6. Choosing the Right Jaw Crusher for Your Recycling Needs

- 7. Maintenance Tips for Jaw Crushers

- 8. Future Trends of Jaw Crushers in Recycling

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Jaw Crushers and Recycling

In today's rapidly evolving industrial landscape, the recycling industry has become increasingly vital. The demand for sustainable waste management solutions is at an all-time high, compelling industries to adopt efficient recycling methods. One of the cornerstone technologies facilitating this transformation is the **jaw crusher**. This article delves into the importance of jaw crushers in the recycling sector, exploring their functions, benefits, and applications.

2. Understanding Jaw Crushers

2.1 What is a Jaw Crusher?

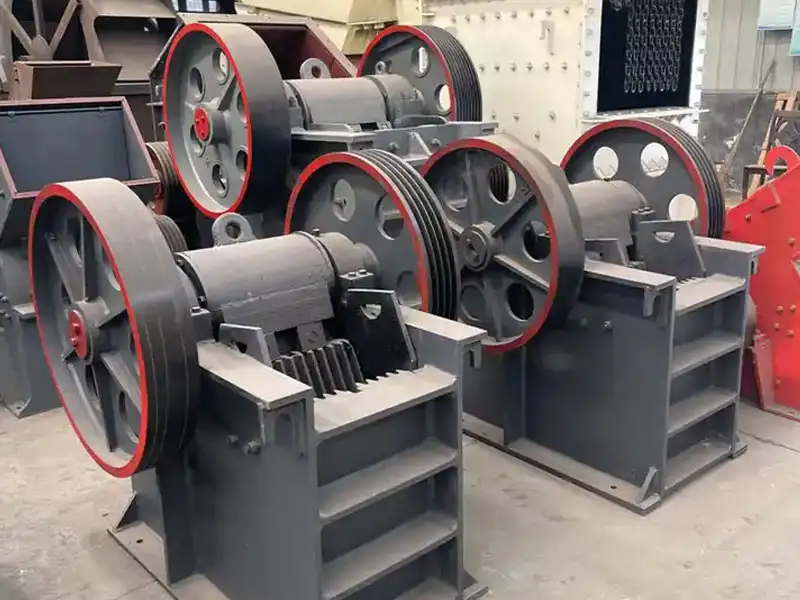

A **jaw crusher** is a heavy-duty machine designed to crush large rocks or ore in mining and construction operations. Unlike other crushers, jaw crushers utilize a pair of **jaw plates** to compress material, breaking it down into smaller, manageable pieces. Their robust construction and advanced technology make them indispensable in the recycling industry.

2.2 How Do Jaw Crushers Work?

Jaw crushers operate on a straightforward principle: as the material enters between the two jaws, the stationary jaw and the movable jaw, it is subjected to compression. The movable jaw reciprocates, crushing the material against the stationary jaw. This process efficiently breaks down even the toughest materials, making jaw crushers highly effective for recycling concrete, asphalt, and other debris.

3. Types of Jaw Crushers in the Recycling Sector

There are several types of jaw crushers utilized in the recycling industry, each designed to cater to specific applications and material types:

1. **Single Toggle Jaw Crushers**: Known for their simplicity and ease of maintenance, these crushers are ideal for processing softer materials.

2. **Double Toggle Jaw Crushers**: With a more complex mechanism, double toggle crushers are suitable for handling harder and more abrasive materials. They offer higher productivity and are capable of crushing larger sizes.

3. **Mobile Jaw Crushers**: These portable units are designed for on-site crushing, providing flexibility and convenience for recycling operations. They are particularly useful in demolition projects where materials need to be processed directly at the site.

4. Key Benefits of Jaw Crushers in Recycling

Jaw crushers provide numerous benefits to the recycling industry, including:

1. **Enhanced Material Reduction**: With high crushing ratios, jaw crushers can efficiently reduce large pieces of material into smaller fragments, facilitating further processing.

2. **Versatility**: Capable of handling a wide range of materials including concrete, glass, and metals, jaw crushers adapt easily to different recycling applications.

3. **Durability and Longevity**: Built to withstand heavy use, jaw crushers require minimal maintenance, ensuring long operational life and reduced downtime.

4. **Energy Efficiency**: Modern jaw crushers are designed for optimal energy consumption, reducing operational costs while maximizing output.

5. **Improved Safety**: Incorporating advanced safety features, jaw crushers minimize the risk of accidents in recycling facilities.

5. Applications of Jaw Crushers in the Recycling Industry

The versatility of jaw crushers allows them to be used in various recycling applications, including:

- **Construction and Demolition Waste**: Jaw crushers are frequently used to process rubble from demolished buildings, converting it into reusable aggregates.

- **Metal Recycling**: They efficiently break down scrap metal, making it easier to separate and recycle valuable metals.

- **Glass Recycling**: Crushing glass into cullet facilitates the recycling process, helping manufacturers create new glass products.

- **Asphalt Recycling**: Jaw crushers play a critical role in reclaiming asphalt from old roads, allowing for its reuse in new pavement.

6. Choosing the Right Jaw Crusher for Your Recycling Needs

Selecting the appropriate jaw crusher for your recycling operation involves several considerations:

- **Material Type**: Understand the types of materials you will be processing. Softer materials may not require the same specifications as harder, more abrasive ones.

- **Capacity Requirements**: Assess the volume of material you need to process daily. This will help determine the size and output capacity of the jaw crusher you need.

- **Mobility Needs**: If your operations require processing materials on-site, consider choosing a mobile jaw crusher for added convenience.

- **Budget Constraints**: Evaluate your budget while considering both initial purchase costs and long-term operational expenses, including maintenance and energy consumption.

7. Maintenance Tips for Jaw Crushers

To ensure optimal performance and longevity of jaw crushers, regular maintenance is crucial. Here are some essential maintenance tips:

1. **Regular Inspections**: Conduct routine checks on wear parts, including jaw plates and bearings, to identify and address wear and tear early.

2. **Lubrication**: Maintain proper lubrication of moving parts to reduce friction and prevent overheating.

3. **Cleaning**: Keep the crusher clean to prevent material buildup, which can lead to operational inefficiencies.

4. **Monitor Performance**: Track the performance metrics of your jaw crusher to identify any drops in efficiency or output.

8. Future Trends of Jaw Crushers in Recycling

As technology evolves, the future of jaw crushers in the recycling industry looks promising. Some emerging trends include:

- **Smart Technology Integration**: The incorporation of IoT devices and AI for real-time monitoring and predictive maintenance, enhancing operational efficiency.

- **Sustainability Focus**: Increased emphasis on using environmentally friendly materials and practices in manufacturing jaw crushers.

- **Enhanced Automation**: Advancements in automation technologies, allowing for more efficient material handling and processing in recycling operations.

9. Frequently Asked Questions (FAQs)

1. What types of materials can jaw crushers process?

Jaw crushers can efficiently process a wide range of materials, including concrete, asphalt, metals, glass, and various types of rocks.

2. How do I maintain a jaw crusher?

Regular inspections, lubrication, cleaning, and monitoring performance metrics are critical for maintaining a jaw crusher effectively.

3. What is the average lifespan of a jaw crusher?

With proper maintenance, jaw crushers can last for many years, often exceeding a decade of operational life.

4. Are mobile jaw crushers as effective as stationary ones?

Yes, mobile jaw crushers are designed to provide similar performance levels as stationary crushers, with the added benefit of portability.

5. How do I choose the right jaw crusher for my recycling operation?

Consider factors such as material type, capacity requirements, mobility needs, and budget constraints when selecting a jaw crusher.

10. Conclusion

In conclusion, jaw crushers are integral to the recycling industry, providing efficient and effective solutions for material processing. Their ability to handle a diverse range of materials, combined with their robust construction and low maintenance requirements, makes them a preferred choice for recycling operations worldwide. As we advance towards a more sustainable future, the role of jaw crushers will undoubtedly expand, driving innovation and efficiency in waste management practices. Investing in the right jaw crusher is a crucial step for any recycling facility aiming to optimize its operations and contribute to environmental sustainability.

PREVIOUS: