The Best Applications for Small Jaw Crushers in Industry

Jan 25,2026

The Best Applications for Small Jaw Crushers in Industry

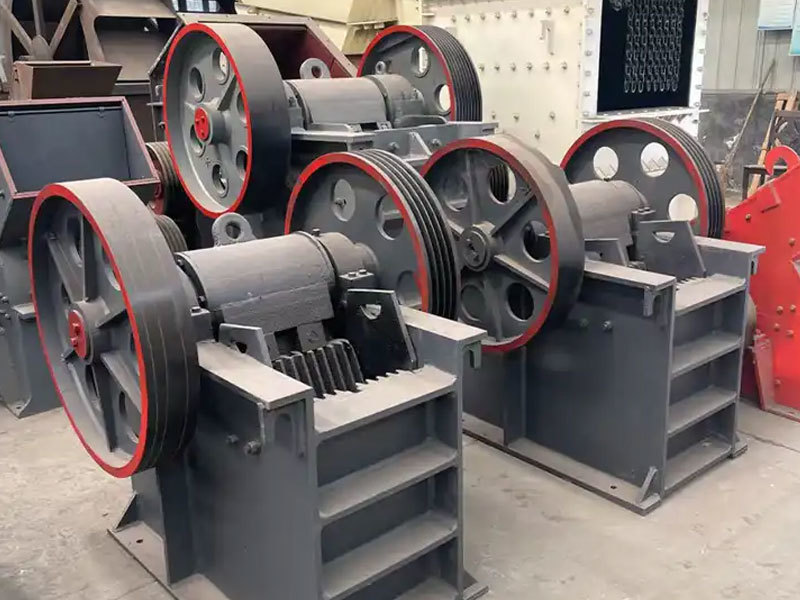

Introduction to Small Jaw Crushers

Small jaw crushers are invaluable equipment in the manufacturing and processing sector. They are designed to crush materials into smaller, manageable sizes, making them crucial for a variety of industries. These machines not only enhance efficiency but also improve the overall productivity of operations by ensuring that raw materials are processed effectively. In this comprehensive article, we will delve into the best applications for small jaw crushers, outlining their significance across different industrial sectors.

Understanding the Functionality of Small Jaw Crushers

Small jaw crushers operate on a simple principle: they use compressive force to break down materials. The crushing action occurs between a stationary and a moving jaw, where the material is fed into the top entrance and crushed between the jaws. The result is finely crushed material that can be used for various applications. Their compact size makes them ideal for smaller operations or sites with limited space.

The Advantages of Using Small Jaw Crushers

- **Versatility**: Small jaw crushers can handle a wide range of materials, including rocks, ores, and even construction waste.

- **Portability**: Their compact size allows for easy transportation and setup at different job sites.

- **Cost-Effectiveness**: These machines are often more affordable than larger crushers, making them accessible for small to medium-sized enterprises.

- **Efficiency**: With high crushing ratios, small jaw crushers can process materials quickly, saving time and labor costs.

Primary Applications in Various Industries

1. Mining and Aggregate Processing

In the mining industry, small jaw crushers are used extensively for ore processing. They crush large rocks into smaller pieces, allowing for easier transport and further processing. In aggregate processing, they help in producing high-quality gravel and stone for construction projects. By efficiently breaking down materials, small jaw crushers contribute to a more streamlined extraction and production process.

2. Construction and Demolition

The construction industry frequently utilizes small jaw crushers for recycling concrete and asphalt. These machines can crush old structures into reusable materials, reducing waste and promoting sustainability. By recycling these materials, construction companies can save on costs while minimizing their environmental impact. Additionally, small jaw crushers can be employed to break down large boulders or rocks found at construction sites, facilitating smoother operations.

3. Environmental and Waste Management

Small jaw crushers play a vital role in waste management by processing recyclable materials. These machines are effective in crushing plastic, wood, and metal waste, which can then be sorted and repurposed. This application is particularly significant as industries move towards more sustainable practices. By converting waste into usable materials, small jaw crushers help reduce landfill contributions and promote a circular economy.

4. Quarrying Operations

Quarrying operations often require the extraction of hard materials like limestone, granite, and sandstone. Small jaw crushers are ideal for breaking these materials down into smaller sizes for easier handling and transport. They are used in various stages of the quarrying process, from initial crushing to final sizing, ensuring that the end products meet specific market requirements.

5. Laboratory and Research Facilities

In laboratory settings, small jaw crushers are invaluable for sample preparation. They allow researchers to crush and reduce the size of rocks and minerals for analysis without requiring large, cumbersome equipment. This flexibility makes small jaw crushers an essential tool for geological and material science research.

Choosing the Right Small Jaw Crusher for Your Needs

When selecting a small jaw crusher, several factors must be considered to ensure it meets your specific requirements.

1. Material Type

Understanding the type of material you will be processing is crucial. Different small jaw crushers are designed to handle various materials, so it's essential to choose one that matches your needs.

2. Size and Capacity

Evaluate the size and throughput capacity of the crusher. Smaller machines may be more suitable for limited space, but ensure they can handle your expected workload efficiently.

3. Power Source

Consider the power requirements of the crusher. Some models operate on electricity, while others may use diesel or other fuel types. Choose a power source that aligns with your operational capabilities.

4. Maintenance and Support

Look into the maintenance needs of the small jaw crusher. A machine that is easy to maintain will save you time and money in the long run. Additionally, consider the availability of support and spare parts from the manufacturer.

Innovative Features of Modern Small Jaw Crushers

Recent advancements in technology have led to the development of modern small jaw crushers that incorporate innovative features, enhancing their efficiency and usability.

1. Adjustable Jaw Settings

Many modern models allow operators to adjust the jaw settings easily. This feature enables precise control over the size of the output material, which is crucial for specific applications.

2. Enhanced Safety Features

Safety is paramount in any industrial operation. Newer small jaw crushers come equipped with safety features such as automatic shut-off systems and protective guards, ensuring safer operation for users.

3. Advanced Material Handling Systems

Contemporary crushers often integrate advanced material handling systems that facilitate the easier loading and unloading of materials. This innovation reduces manual labor and increases overall productivity.

4. Eco-Friendly Designs

As industries strive for sustainability, many small jaw crushers now feature eco-friendly designs. These models minimize noise and dust emissions, aligning with environmental regulations and standards.

Case Studies: Successful Implementations of Small Jaw Crushers

Examining real-world examples can provide valuable insights into the effective applications of small jaw crushers in various industries.

1. Case Study: Recycling Plant Efficiency

A recycling plant integrated a small jaw crusher into its operation to enhance its processing capabilities. The addition of this machine allowed them to significantly increase their throughput, reducing costs and minimizing waste. The processed materials were then sold back to manufacturers, demonstrating a successful circular economy model.

2. Case Study: Mining Operations

In a mining operation, a small jaw crusher was utilized to process ore, improving the extraction process. This implementation allowed the company to increase its productivity by 30%, resulting in higher profit margins and reduced operational downtime.

FAQs About Small Jaw Crushers

1. What materials can a small jaw crusher process?

Small jaw crushers can process a variety of materials, including rocks, ores, concrete, and construction waste.

2. Are small jaw crushers portable?

Yes, small jaw crushers are designed to be portable and can be easily transported between job sites.

3. How do I maintain a small jaw crusher?

Regular maintenance includes checking for wear and tear, lubricating moving parts, and ensuring that the machine is clean and free from debris.

4. What is the typical lifespan of a small jaw crusher?

The lifespan of a small jaw crusher can vary based on usage and maintenance but often ranges from 10 to 15 years with proper care.

5. Can small jaw crushers be used for laboratory applications?

Yes, small jaw crushers are commonly used in laboratories for sample preparation and material analysis.

Conclusion

Small jaw crushers serve a multitude of applications across various industries, proving to be indispensable in enhancing productivity and sustainability. From mining to recycling, these compact machines offer versatility and efficiency that larger crushers cannot match. By understanding the specific applications and features of small jaw crushers, businesses can make informed decisions that will contribute to their operational success. Investing in the right small jaw crusher can lead to significant improvements in processing capabilities, ultimately driving growth and profitability in an increasingly competitive market.