Choosing Between Fixed and Portable Jaw Crushers: A Comprehensive Guide

Feb 19,2026

Choosing Between Fixed and Portable Jaw Crushers: A Comprehensive Guide

Table of Contents

- Introduction

- Understanding Jaw Crushers

- What Are Fixed Jaw Crushers?

- Advantages of Fixed Jaw Crushers

- What Are Portable Jaw Crushers?

- Advantages of Portable Jaw Crushers

- Key Considerations for Choosing

- Cost Analysis: Fixed vs. Portable Jaw Crushers

- Application Suitability

- Maintenance Requirements

- Conclusion

- FAQs

Introduction

When it comes to crushing rocks and other materials, **jaw crushers** are among the most popular machines in the construction and mining industries. Their effectiveness in breaking down tough materials makes them indispensable in various operations. However, selecting the right type of jaw crusher—**fixed or portable**—can significantly impact your operation's efficiency and cost-effectiveness. In this guide, we will explore the advantages and disadvantages of both options, along with critical factors to consider when choosing between fixed and portable jaw crushers.

Understanding Jaw Crushers

Jaw crushers are heavy-duty machines designed to break down large rocks into smaller, manageable sizes. They use compressive force to crush materials, with a fixed jaw and a movable jaw working in tandem. This mechanism is vital for various applications, including mining, quarrying, and recycling.

How Jaw Crushers Work

The basic structure of a jaw crusher consists of two jaws: one stationary (fixed) and the other movable. The material is fed into the crushing chamber, where the movable jaw exerts force against the fixed jaw, breaking down the materials. The size of the output product can be adjusted by altering the spacing between the jaws.

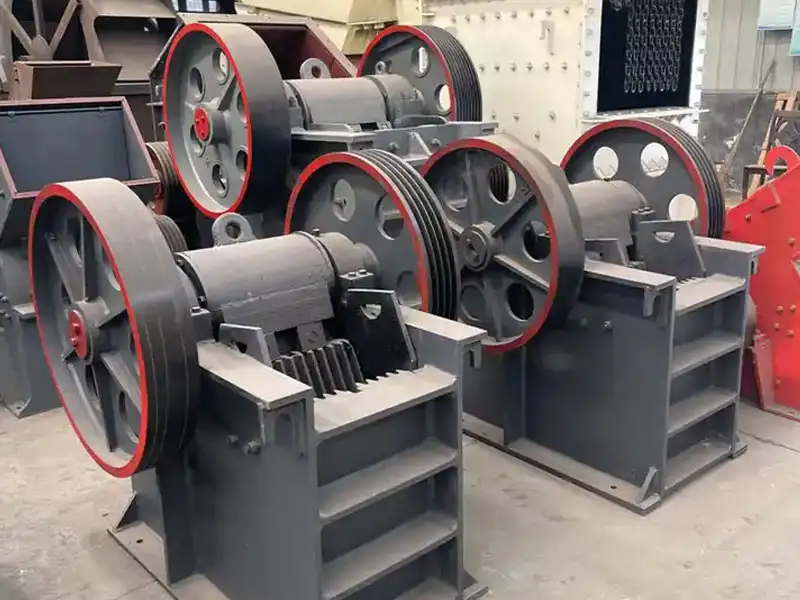

What Are Fixed Jaw Crushers?

Fixed jaw crushers, often referred to as **stationary jaw crushers**, are permanently installed in a specific location. They are typically used in large-scale mining or aggregate production settings where high production volumes are necessary.

Characteristics of Fixed Jaw Crushers

Fixed jaw crushers are designed for high performance and durability. They are robust machines that can handle large quantities of material efficiently. These crushers are often part of fixed plant operations, where they can be integrated into larger processing systems.

Advantages of Fixed Jaw Crushers

Choosing fixed jaw crushers offers several benefits, especially for large operations:

1. High Throughput

Fixed jaw crushers generally offer higher throughput compared to portable models. Their ability to handle large volumes makes them ideal for high-demand environments.

2. Greater Durability

These machines are built to last, often constructed with high-quality materials to withstand the rigors of constant use. They are less prone to wear and tear compared to portable units.

3. Cost-Effectiveness for Large Operations

For businesses with significant crushing needs, fixed jaw crushers can be more cost-effective over time. Although the initial investment may be higher, their long life and efficiency can lead to considerable savings.

What Are Portable Jaw Crushers?

Portable jaw crushers, also known as **mobile jaw crushers**, offer a flexible solution for operations requiring mobility and adaptability. These machines can be easily transported between job sites, making them suitable for smaller projects or temporary setups.

Characteristics of Portable Jaw Crushers

Portable jaw crushers are designed for versatility. They can be easily set up and dismantled, allowing for quick relocation. This flexibility makes them popular among contractors and smaller operations.

Advantages of Portable Jaw Crushers

Portable jaw crushers present unique advantages that cater to specific operational needs:

1. Mobility

The standout feature of portable jaw crushers is their mobility. They can be transported easily on trailers or trucks, allowing for quick setup on various job sites.

2. Versatility

These machines can be used in different applications and environments, from quarries to construction sites. This flexibility allows companies to adapt to changing project requirements.

3. Reduced Setup Time

Portable jaw crushers require less time for setup and breakdown, making them ideal for temporary projects or locations where quick implementation is necessary.

Key Considerations for Choosing

When deciding between fixed and portable jaw crushers, several key factors should be considered to ensure the best fit for your operation:

1. Production Volume

Assess your expected production volume. Fixed jaw crushers are ideal for high-volume operations, while portable models may suffice for smaller projects.

2. Site Conditions

Consider the working environment. If you operate in multiple locations or need to move equipment frequently, portable jaw crushers may be the better choice.

3. Budget Constraints

Evaluate your budget. Fixed jaw crushers generally involve higher upfront costs, while portable models may be less expensive initially but could incur higher operational costs over time.

Cost Analysis: Fixed vs. Portable Jaw Crushers

Understanding the cost implications of both fixed and portable jaw crushers is crucial for making an informed decision.

1. Initial Investment

Fixed jaw crushers typically require a more substantial initial investment due to their size and durability. On the other hand, portable jaw crushers are often more budget-friendly at the outset.

2. Operational Costs

Operational costs can vary significantly between the two types. Fixed jaw crushers may have lower operational costs due to their efficiency and durability, while portable crushers may incur higher maintenance expenses due to frequent relocations and setup.

3. Long-Term Financial Impact

Evaluate the long-term financial impact. Companies with high production needs may find that a fixed jaw crusher is more cost-effective over several years, despite the higher initial price.

Application Suitability

Different applications call for different types of jaw crushers. Understanding where each type shines can guide your decision:

1. Fixed Jaw Crushers in Mining

In large-scale mining operations, fixed jaw crushers excel by handling vast quantities of material with consistent output.

2. Portable Jaw Crushers for Construction

For contractors and construction projects requiring mobility, portable jaw crushers offer the flexibility to move to various job sites without hassle.

Maintenance Requirements

Maintaining jaw crushers is critical for their longevity and performance. Each type has different maintenance requirements to consider:

1. Fixed Jaw Crushers

Fixed jaw crushers generally require less frequent maintenance due to their robust construction. Regular inspections and routine maintenance can keep them running efficiently.

2. Portable Jaw Crushers

Portable jaw crushers may require more maintenance due to their mobility and frequent relocations. It's essential to keep a consistent maintenance schedule to ensure optimal performance.

Conclusion

Choosing between fixed and portable jaw crushers depends largely on your operational needs, budget, and project requirements. Fixed jaw crushers offer durability and high throughput, making them suitable for large operations. Conversely, portable jaw crushers provide flexibility and ease of transport, ideal for construction projects and smaller applications. By evaluating production volume, site conditions, and financial implications, you can make an informed decision that aligns with your project goals.

FAQs

1. What are the main differences between fixed and portable jaw crushers?

Fixed jaw crushers are stationary and built for high-volume production, while portable jaw crushers are designed for mobility and versatility.

2. Which type of jaw crusher is more cost-effective?

The cost-effectiveness depends on your specific needs. While fixed jaw crushers may have higher initial costs, they can be more economical for large-scale operations in the long run.

3. Can portable jaw crushers handle large volumes of material?

Portable jaw crushers can handle substantial volumes, but they may not match the throughput levels of fixed models in high-demand industries.

4. How do I choose the right jaw crusher for my operation?

Consider factors such as production volume, site conditions, budget, and application suitability when making your choice.

5. What maintenance is required for jaw crushers?

Regular inspections, lubrication, and timely repairs are essential for both fixed and portable jaw crushers to ensure efficient operation.

PREVIOUS: