Innovative Shaftless Drum Screen Revolutionizes Material Screening Efficiency

Aug 13,2025

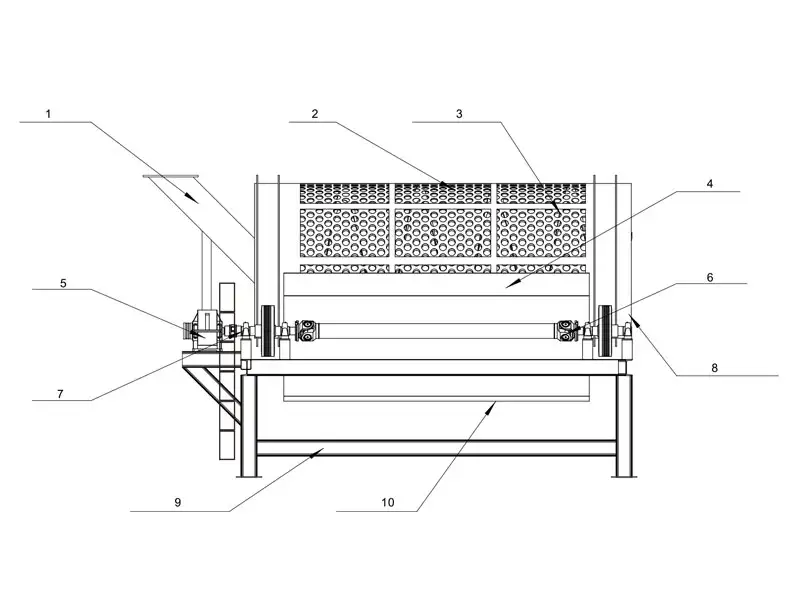

In recent years, the demand for efficient and environmentally friendly material screening solutions has surged across industries such as mining, recycling, and construction. The shaftless drum screen has emerged as a cutting-edge technology that addresses these challenges, offering unprecedented performance and operational advantages over traditional screening systems. Unlike conventional drum screens with a central shaft, the shaftless design eliminates the shaft completely, allowing for a more flexible and versatile operation that can handle a variety of materials, including sticky, wet, and oversized substances that typically clog standard screens.

The shaftless drum screen operates with high durability and minimal maintenance requirements. By removing the central shaft, the risk of blockage or material accumulation is significantly reduced, resulting in higher throughput and a more consistent screening process. This technology also enhances energy efficiency, as the reduced friction and mechanical complexity decrease overall power consumption. Companies adopting shaftless drum screens have reported substantial improvements in processing capacity, operational uptime, and cost-effectiveness, making it a preferred choice for large-scale material processing plants.

In recycling applications, the shaftless drum screen plays a crucial role in separating various fractions of waste materials, such as construction debris, wood, and plastic. Its ability to handle challenging materials without frequent maintenance interruptions significantly improves the efficiency of recycling operations. Moreover, its modular design enables easy integration into existing production lines, allowing businesses to upgrade their screening capabilities without extensive restructuring.

Environmental benefits are another key advantage of the shaftless drum screen. By reducing the energy required for screening and minimizing the risk of material contamination, it supports more sustainable production processes. Furthermore, its robust construction ensures a long service life, reducing the need for frequent replacements and contributing to lower industrial waste.

Industry experts predict that the shaftless drum screen will continue to grow in popularity as manufacturers seek smarter, more sustainable, and cost-efficient solutions for material separation. With its innovative design, operational reliability, and versatility across multiple applications, the shaftless drum screen is positioned as a transformative technology in the modern material processing landscape.

In conclusion, the shaftless drum screen represents a significant step forward in screening technology. Its ability to efficiently process a wide range of materials, combined with lower maintenance needs, energy efficiency, and environmental advantages, makes it an indispensable tool for industries worldwide. As the demand for advanced screening solutions rises, the adoption of shaftless drum screens is set to expand, driving innovation and improving operational outcomes across multiple sectors.