Enhancing Industrial Efficiency with Heavy Plate Feeders

Aug 14,2025

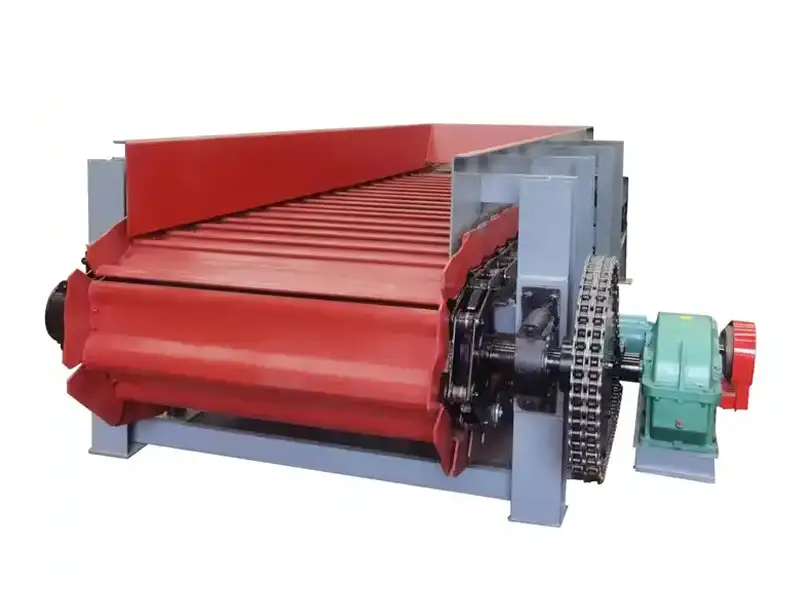

In modern industrial operations, efficiency, precision, and reliability are paramount. The Heavy Plate Feeder has emerged as a vital piece of equipment in metal processing and fabrication industries, streamlining the movement and handling of large steel plates with remarkable efficiency. Designed to handle heavy-duty workloads, these feeders play a crucial role in automating processes and reducing manual labor, thereby improving overall productivity.

A Heavy Plate Feeder is engineered to transport thick metal plates from storage to processing machines such as shears, presses, and rolling mills. Its robust construction allows it to manage extremely heavy loads while maintaining precise alignment. This ensures that plates are fed smoothly into cutting or forming machines, minimizing the risk of damage and enhancing operational safety. Modern feeders are equipped with advanced hydraulic or electric systems, providing consistent force and controlled movement, which is essential for handling large and heavy materials.

Industrial facilities benefit greatly from integrating Heavy Plate Feeders into their workflows. By automating the feeding process, companies can reduce labor costs and improve production speed. The accuracy of these feeders also ensures minimal material wastage, which is particularly important when working with expensive steel plates. Additionally, their durability and low maintenance requirements make them a long-term investment for manufacturers seeking reliability and cost efficiency.

Technological advancements have expanded the capabilities of Heavy Plate Feeders. Many models now feature programmable controls, allowing operators to set precise feeding rates, angles, and sequences for different plate sizes and thicknesses. Some feeders include integrated sensors and safety mechanisms to detect misalignment or overload, ensuring both machine protection and operator safety. These innovations make heavy plate handling safer, faster, and more consistent than ever before.

The versatility of Heavy Plate Feeders makes them indispensable across a wide range of industries. From shipbuilding and construction to steel fabrication and automotive manufacturing, these feeders enhance operational efficiency and reduce bottlenecks in production lines. Their ability to handle diverse plate sizes, thicknesses, and weights allows manufacturers to maintain a flexible and high-capacity workflow.

Environmental and ergonomic considerations are also increasingly addressed in modern Heavy Plate Feeders. Energy-efficient motors and systems reduce power consumption, while ergonomic designs reduce strain on operators, promoting a safer and more sustainable working environment. This aligns with broader industry trends towards greener and more worker-friendly manufacturing solutions.

In conclusion, the Heavy Plate Feeder is a cornerstone of modern metal processing operations. By combining strength, precision, and automation, it enhances productivity, reduces labor demands, and ensures material handling safety. As industries continue to modernize, the adoption of advanced heavy plate feeding technology represents a key step towards more efficient, reliable, and sustainable manufacturing practices.

PREVIOUS: