Introduction

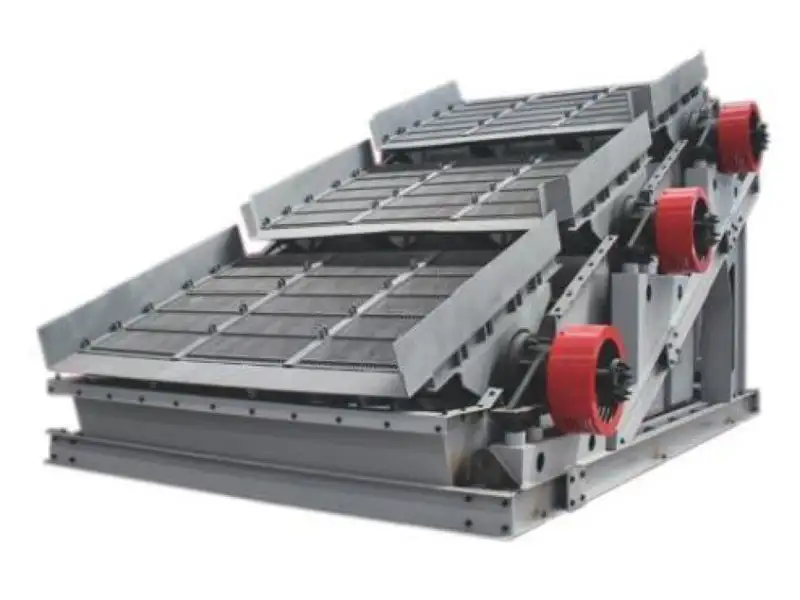

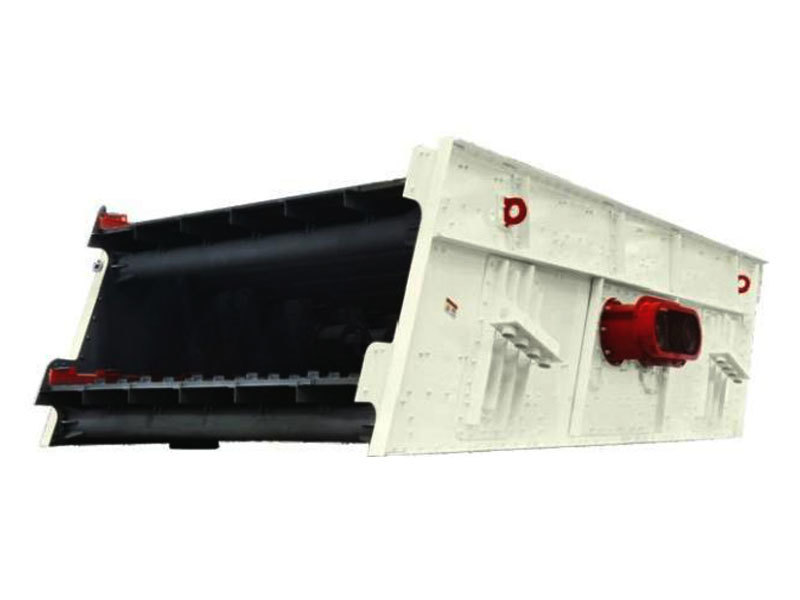

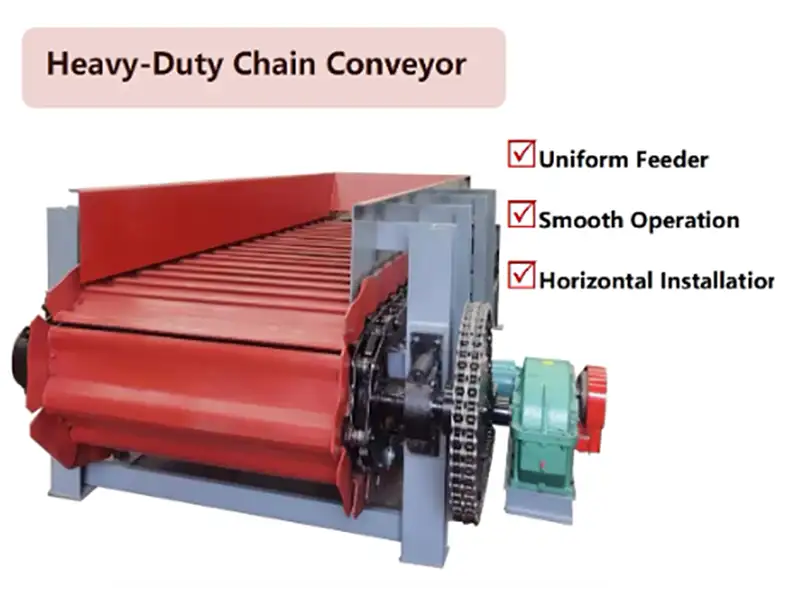

Heavy-duty chain conveyor is a kind of continuous material conveying machinery, which is used for continuous and even feeding to crusher, conveyor or other mechanical equipment along horizontal or inclined direction, applicable to extra-large and medium-sized mining equipments, production line of large and medium-sized cement plants, and it can work reliably in high temperature and high humidity in bad environment, especially it is more suitable for transporting large, high temperature and sharp materials, and it can work reliably in the open air, humid and bad environment. It can work reliably in open air, wet and harsh environment.

Product classification

1. Heavy-duty chain plate conveyor: suitable for short-distance transportation of lumpy materials with feed size below 1000mm.

2. Medium chain plate conveyor: it is suitable for short-distance conveying materials with feeding granularity below 400mm, transporting materials with bulk density less than 2400kg/m3, block weight less than 500kg and temperature below 400°C.

3. Light chain plate conveyor: it is suitable for short-distance conveying of lumpy materials with feeding size below 160mm, transporting materials with loose density less than 1200kg/m3, lump weight less than 140kg and temperature below 350°C.

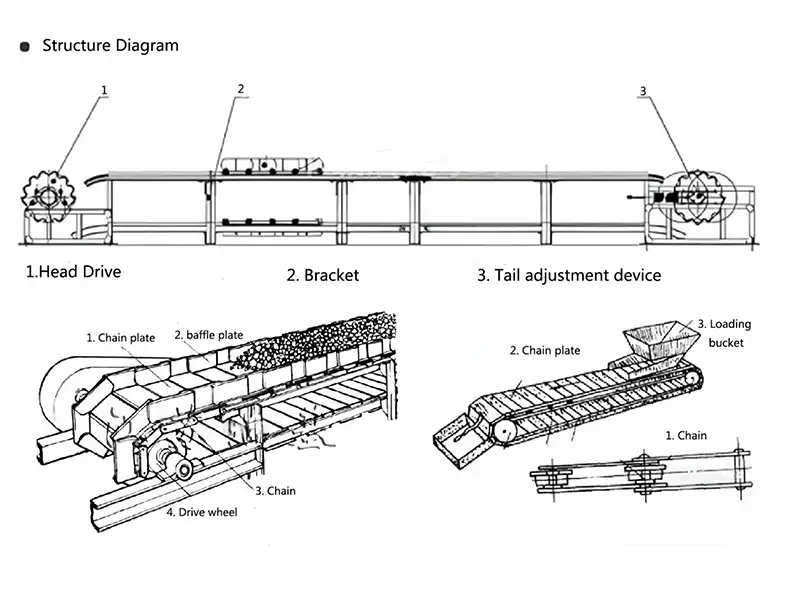

Structure Composition

The chain conveyor is mainly composed of driving device, tensioning device, driving chain, chain plate, frame, rollers (or chute), redirecting sprocket, cleaning device and other parts. Among them, the driving device is the power source of the conveyor, and the tensioning device is used to adjust the tension of the chain to ensure the stability of the conveying process; the driving chain and the chain plate are the core components responsible for the actual conveying of materials; the frame, as the supporting structure, carries the weight of the whole conveyor; the rollers or the slideway are used to support the chain plate to reduce the resistance; the reversing sprocket is used to change the direction of movement of the chain; and the cleaning device is used to clean the residues on the chain and the chain plate. Sweeping device is used to clean the residual materials on the chain and chain plate to prevent blockage.

Working Principle

The working principle of chain conveyor is relatively simple and efficient. Its power source is usually provided by a motor, which drives the active sprocket to rotate after deceleration through a speed reducer. The chain on the active sprocket drives the chain plates forward in turn during the rotation process. The chain plates are connected by hinges or pins to form a continuous conveyor belt surface. When the material is placed on the chain plate, with the movement of the chain plate, the material is continuously and smoothly conveyed to the specified position. During the conveying process, baffles and partitions can be set up as required to prevent the materials from scattering or mixing.

Advantageous Features

1. Strong load-bearing capacity: the chain conveyor adopts high-strength chain and chain plate, which can withstand large load and is suitable for conveying heavy materials.

2. Stable operation: chain transmission is stable and reliable, and the connection between chain plates is tight, so the materials are not easy to be scattered during conveying, and the operation is smooth and noiseless.

3. Strong adaptability: the conveying speed, direction and height can be adjusted according to different conveying requirements, and it is suitable for horizontal, inclined and vertical conveying scenarios.

Important attributes

|

Warranty period |

Six months |

Weight (KG) |

29298 |

|

Core components |

PLC, Engine, Motor, Bearing |

Country of origin |

Henan,China |

|

Video factory inspection |

Available |

Mechanical Test Report |

Available |

|

Brand |

ZHOUCHI |

Product Name |

板式给料机 |

|

Function |

Material Handling |

Type |

Scraper conveyor |

|

Brand |

ZHOUCHI |

applications |

coal mining equipment |

|

Quality |

ISO 9001:2008 Certificate |

After-sales service |

Provide professional technical support |

|

installation |

Under guidance |

Other names |

Chain plate feeder |

|

Color |

Customer requirements |

||

Packaging and shipping information

|

Sales unit |

Single item |

Single package dimensions |

1035X594X184 cm |

|

Gross weight of a single product |

29298.000 KG | ||

Keywords

PREVIOUS:

Robust heavy-duty chain plate feeder Reliable steel mill skirt feeder Basic components of mining machinery

Contact Us

Classification

Clients

Case Studies

Certificates