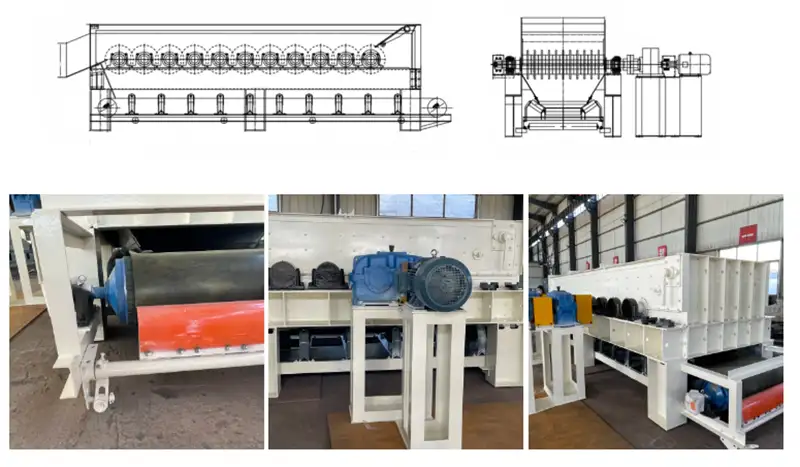

Product Introduction

Working principle

● The motor drives the sprocket through a reducer and coupling, and the sprocket drives the chain to rotate the drum. The drum is usually equipped with a disc or other shaped device. Materials are fed into the equipment and roll and slide on the screen surface under the rotation and tilting motion of the drum.

● Due to the gaps between the joints, small particles (such as soil) smaller than the gaps will fall through the gaps to the bottom of the machine and be discharged by the belt conveyor; while larger pieces of material, such as stones, larger than the gaps will continue to move along the rollers and their axial direction from the screen surface to the discharge end, thereby achieving mud separation.

The purpose of stone separation or material classification.

Structural characteristics

● Power system: Includes an electric motor and reducer, which provide power and control roller speed through a reasonable transmission ratio.

● Roller assembly: Core component, with multiple horizontally arranged rollers equipped with rollers/discs made of high-strength wear-resistant steel.

● Chain and Sprocket System: Connects the rollers to achieve synchronized rotation, made of high-quality alloy steel for wear resistance and durability.

● Screen Housing: Welded steel plates form a closed box to house internal components, providing support and protection while preventing material splashing and dust leakage. All components work together to ensure the equipment operates stably and efficiently for effective mud-stone separation.

Details show

Performance advantages

● It can be used for both dry and wet separation. Dry separation does not require water, conserving water resources and avoiding issues such as sludge treatment and equipment corrosion caused by wet screening. It is particularly suitable for water-scarce regions or scenarios with strict requirements on material moisture content.

● The equipment is less prone to material blockages. It uses the gaps between rollers for screening instead of traditional screens. It can handle materials with high humidity, high viscosity, and high soil content, ensuring continuous and stable operation.

● It has a high screening efficiency. Through the synchronized rotation of multiple drums, combined with reasonable speed and gap design, it can quickly and thoroughly separate materials to meet the processing needs of different production scales.

● High adjustability is another major advantage. The configuration of variable-frequency motors allows flexible adjustment of drum speed and material conveying speed. The drum gaps can also be adjusted according to material particle size to achieve optimal separation results.

● Additionally, the equipment achieves multi-functional use. Besides mud-stone separation, it can also perform feeding and conveying functions, reducing equipment footprint and investment costs. Furthermore, critical components such as screens are made of high-quality alloy steel and undergo meticulous design and processing. They exhibit strong wear resistance and fatigue resistance, ensuring a long service life and stable operation in harsh environments, thereby reducing maintenance and upkeep costs.

Application areas

● In gravel pits, it can separate soil impurities from gravel to improve gravel quality;

● In mining, it can preliminarily screen ore, separate soil and gangue, and improve ore grade;

● In construction waste processing, it can separate solid materials from soil to facilitate resource recovery;

● In municipal solid waste processing, it can separate large debris from soil organic matter;

● In river dredging, it can separate sand, soil, and debris, facilitating river dredging and ecological improvement.

|

Product model |

Screen width |

Screen length |

Processing power |

| GZS1040 | 1000mm | 4000mm | 50-100t/h |

| GZS1540 | 1500mm | 4000mm | 80-150t/h |

| GZS1460 | 1400mm | 6000mm | 100-200t/h |

| GZS3060 | 3000mm | 6000mm | 200-500 t/h |

Important Attributes

|

Type |

Linear vibrating screen |

Voltage |

380V |

|

Core components |

Bearings, gearboxes, gears |

Country of origin |

Henan,China |

|

Weight |

3000 KG |

warranty period |

1年 |

|

Video factory inspection |

Available |

Mechanical Test Report |

Available |

|

Application |

Minerals |

Brand |

Zhouchi |

|

Product Name |

1460 Mud and Stone Separator |

Screen material |

50Cr |

|

Already used |

Grading/filtering/impurity removal |

Production capacity |

300-1500 |

|

Screen size |

10-150mm |

motor power |

15-55KW |

|

Feed size |

<800mm |

Provide after-sales service |

Engineer guidance |

|

Quality |

High quality |

Usage |

Separation screening |

Packaging and shipping information

|

Sales unit |

Single iItem |

Single package dimensions |

XX cm |

Customization options

|

Options |

Minimum order |

Customization fees |

|

Voltage 415v |

1 sets | -- |

|

Power (horsepower) As required |

1 sets | -- |

Keywords

NEXT:

High-efficiency mudstone separator Professional mining construction sand screen Wear-resistant roller design

Contact Us

Classification

Clients

Case Studies

Certificates