Product Description

The GZ series electromagnetic vibrating feeder is widely used in industries such as mining, metallurgy, coal, building materials, light industry, chemicals, power, machinery, and food. It is designed to uniformly and continuously or quantitatively receive materials in block, granular, or powder form from storage bins or hoppers. Examples include zone-fed conveyors, bucket elevators, screening equipment, and more. Feeding materials into crushers, as well as for automatic batching, quantitative packaging, and other applications, and can be used for process automation control to achieve healthy automation of the production process.

Product Advantages

The electromagnetic vibrating feeder is a new type of feeding equipment with the following features compared to other feeding devices:

(1) Compact size, lightweight, simple structure, easy installation, no rotating parts requiring lubrication, convenient maintenance, and low operating costs.

(2) The electromagnetic vibrating conveying feeder operates at a low critical near-resonance state using the principle of mechanical vibration resonance, resulting in lower energy consumption.

(3) Since the feed rate can be adjusted and the feeder can be instantly opened or closed, the feed rate achieves high precision.

(4) The control equipment of this series of electric vibrating feeders uses a thyristor half-wave rectifier circuit; therefore, during operation, the feed rate can be conveniently adjusted by regulating the thyristor firing angle without changing the feed rate, enabling centralized automatic control of the production process.

(5) Since the material in the feed hopper is continuously thrown upward during the feeding process and jumps forward along a parabolic trajectory, the friction loss in the feed hopper is minimal.

(6) This series of electric vibrating machines is not suitable for use in explosive environments.

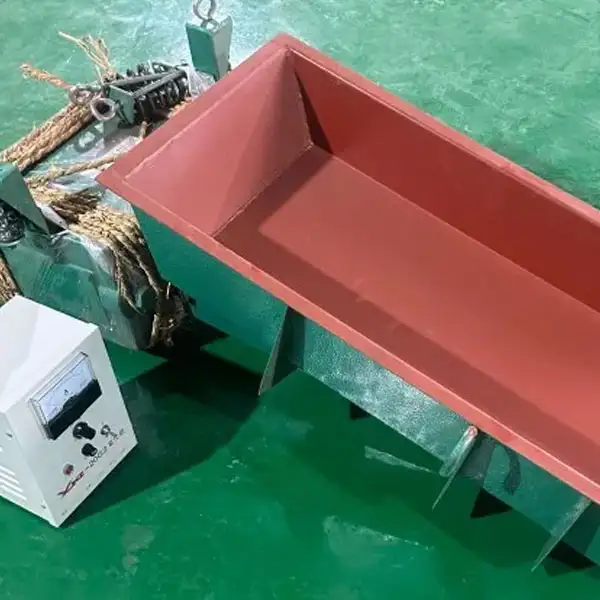

Detailed Image

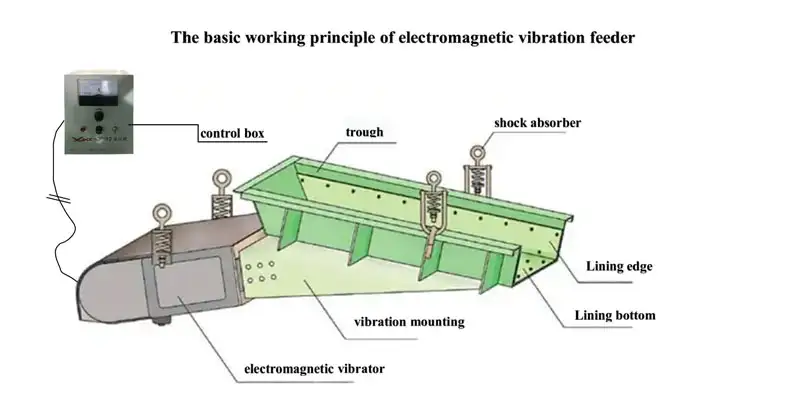

Working Principle & Product Structure

The working principle of the electromagnetic feeder is mainly based on the principle of electromagnetic vibration. The core component of the electromagnetic feeder is the electromagnetic vibrator, which consists of a coil, core, and vibration springs. When current flows through the coil, the generated magnetic field causes the core to experience attractive or repulsive forces, thereby producing vibration. The feed chute mounted on the electromagnetic vibrator also follows the vibration, uniformly and continuously conveying material from the storage bin to the target equipment.

Product Parameter

GZ series electromagnetic vibration feeder series parameters | |||||||||||

Type | Model | Productivity | Feed | double- | power | electric current | effective power | Matching control | Weight | ||

Fundamental | level | -10 | Operating | Representation | |||||||

GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 | 73 | |

GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | 146 | ||||

GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | 217 | ||||

GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | 412 | |||

GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 656 | ||||

GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | 1252 | |

GZ7 | 250 | 350 | 250 | 24.6 | 30 | 3 | XKZ-100G3 | 1920 | |||

GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | 3040 | ||||

GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | 3750 | |||

GZ10 | 750 | 1050 | 500 | 39.4×2 | 32×2 | 4×2 | 6495 | ||||

| GZ11 | 1000 | 1400 | 500 | 47.6×2 | 38.6×2 | 5.5×2 | 7680 | |||

Electromagnetic feeder

Category:

Clients

Case Studies

Certificates