Product Description

Introductory

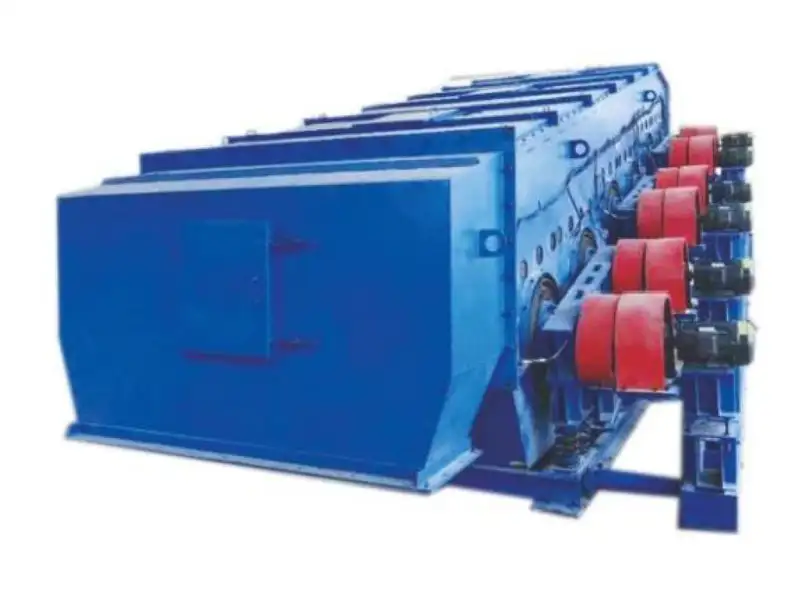

PC400 * 300 Hammer Crusher is suitable for crushing various materials which are brittle, medium-hard and with compressive strength less than 150MPa. The machine is characterized by hammer casting using new technology, wear-resistant, impact-resistant, according to customer requirements, adjust the required particle size, while the structure of the body sealed to solve the problem of dust pollution and dust leakage in the crushing workshop. And the overall design is beautiful, compact structure, less wearing parts, easy maintenance and other advantages of the product is upgraded.

Working Principle

Hammer crusher mainly relies on impact crushing materials. The crushing process is roughly like this: the material enters the crusher and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head. From the high speed to the body of the frame baffle, screen rod, at the same time, the material collided with each other, was broken many times, less than the screen gap, the material discharged from the gap. A single larger material, again on the screen mesh hammering, grinding, extrusion and crushing, the material is hammered out of the gap, so as to obtain the desired product size. Hammer crusher is divided into reversible and irreversible two kinds, reversible hammer crusher rotor can be reversed, generally used for fine crushing; irreversible hammer crusher rotor is not reversible, generally used for medium crushing.

3.Product Advantage

Suitable for a wide range of materials

Hammer crusher series products are suitable for crushing medium hardness and brittle materials, such as limestone, coal, salt, white, gypsum, alum, bricks, tiles, gangue and so on. The compressive strength of the crushed material is 150 MPa, which can be used in cement, coal processing, power generation, building materials, chemical industry, metallurgy and compound fertilizer industry.

Reasonable and efficient hammer head design

The hammer crusher is made of high quality premium steel and undergoes strict heat treatment process so as to obtain a single austenitic structure. The service life is more than five times higher than the original products such as manganese steel and steel rails, and the working efficiency is more than 30%.

Energy efficient triple crushing

The crushing method of hammer crusher is energy driven hammer head striking crushing. Secondly, the material struck by the hammer head hits the counter plate at high speed, and the rebound stone of the counter plate hits the material struck by the hammer head again. There are three kinds of crushing force, but only consume the energy to drive the hammer head, so the hammer crusher can be energy efficient.

Stable operation and good crushing effect

Hammer crusher is designed with beautiful appearance and compact structure, each part is strictly screened to realize long time normal operation, and the crushing ratio is large, the product size is uniform, generally cubic, and there will be no excessive crushing.

|

Attribute Name |

Attribute Data |

Attribute Name |

Attribute Data |

|

Place of Origin |

Xinxiang, Henan |

Mould |

PC400 * 300 |

|

Motor Power (kW) |

11 |

Feed Size |

≤ 100 mm |

|

Machine Weight (kg) |

800 |

Discharge Granularity |

≤ 10 mm |

|

Capacity (t/h) |

5-10 |

Areas of Application |

Crushing brittle, medium hardness, compressive strength less than 150MPa of various materials |

Previous

Next

Previous:

Next:

Vertical Crusher

Category:

Clients

Case Studies

Certificates