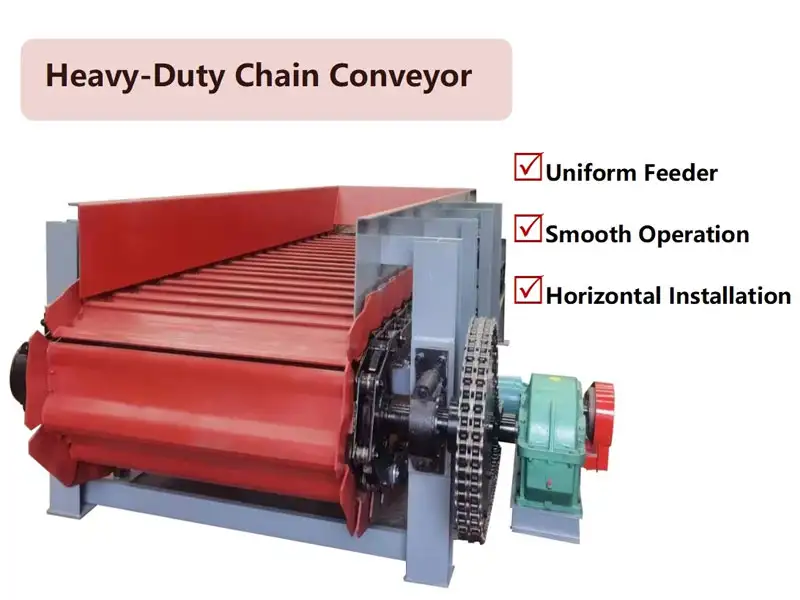

Product Description

Introduction

Heavy-duty chain conveyors are continuous material handling machines used to feed materials continuously and uniformly along horizontal or inclined directions to crushers, conveyors, or other mechanical equipment. They are suitable for extra-large and medium-sized mining equipment, large and medium-sized cement plant production lines, and can operate reliably in harsh environments with high temperatures and humidity. In particular, they are more suitable for transporting large, high-temperature, and sharp materials and can operate reliably in open-air, humid, and harsh environments. It can operate reliably in outdoor, humid, and harsh environments.

Product Categories

1. Heavy-duty chain conveyor: Suitable for short-distance transportation of bulk materials with feed sizes below 1,000 millimeters.

2. Medium-duty chain conveyor: Suitable for short-distance transportation of materials with feed particle sizes below 400 millimeters, conveying materials with a bulk density less than 2,400 kilograms per cubic meter, block weights less than 500 kilograms, and temperatures below 400 °C.

3. Light-duty chain conveyor: Suitable for short-distance conveying of bulk materials with feed sizes up to 160 mm, conveying materials with a bulk density less than 1200 kg/m³, block weights less than 140 kg, and temperatures below 350 °C.

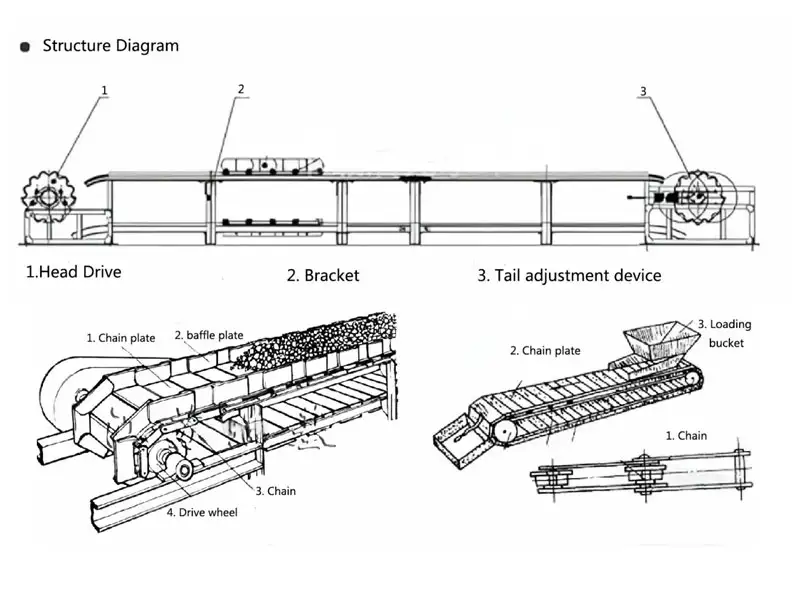

Structural Composition

A chain conveyor primarily consists of a drive unit, tensioning device, drive chain, chain plates, frame, rollers (or slides), redirecting sprockets, and cleaning devices. Among these, the drive unit serves as the power source for the conveyor, while the tensioning device adjusts the chain's tension to ensure stable operation during material handling. The drive chain and chain plates are the core components responsible for actual material transportation. The frame, as the supporting structure, bears the weight of the entire conveyor; rollers or slides are used to support the chain plates, reducing resistance; redirecting sprockets are used to change the direction of the chain's movement; and the cleaning device is used to remove residues from the chain and chain plates. The cleaning device removes residual materials from the chain and chain plates to prevent blockages.

Working Principle

The working principle of a chain conveyor is relatively simple and highly efficient. Its power source is typically provided by an electric motor, which drives the drive sprocket through a reducer to rotate at a reduced speed. During rotation, the chain on the drive sprocket sequentially drives the chain plates forward. The chain plates are connected via hinges or pins, forming a continuous conveying surface. When materials are placed on the chain plates, they are continuously and smoothly transported to the designated location as the chain plates move. During the conveying process, guards and partitions can be installed as needed to prevent material scattering or mixing.

Advantages and Features

1. High load-bearing capacity: Chain conveyors use high-strength chains and chain plates, capable of withstanding heavy loads, making them suitable for conveying heavy objects.

2. Smooth operation: The chain drive is stable and reliable, with chain plates tightly connected, ensuring materials do not scatter during conveying, resulting in smooth operation with minimal noise.

3. High adaptability: Conveying speed, direction, and height can be adjusted according to different conveying requirements, making it suitable for horizontal, inclined, and vertical conveying scenarios.

Previous

Previous:

Standard chain conveyor

Category:

Clients

Case Studies

Certificates