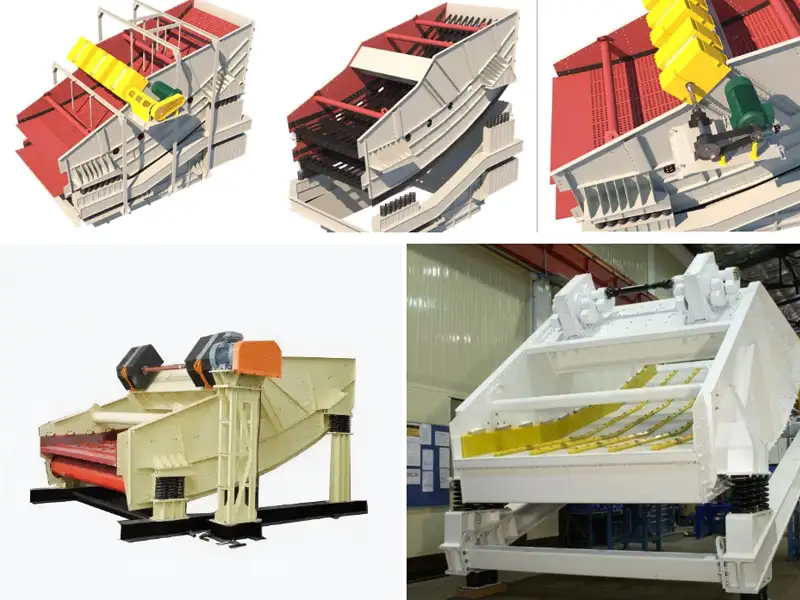

Product Features

Banana Screen / Uniform Thickness Linear Screen

The screening surface of the banana screen is arranged in multiple sections at varying angles, typically ranging from 3 to 7 sections. The feed end features a steep incline, while the discharge end's angle gradually decreases. The steep incline at the feed end accelerates material movement and rapid stratification, facilitating passage through the screen mesh. As the inclination angle decreases and material gradually diminishes on the screen surface, flow velocity slows. This maintains a relatively consistent material thickness across the screen surface, enhancing interlayer interaction and promoting the passage of particles smaller than the screen aperture size. Consequently, screening efficiency and de-mediation efficiency are improved.

Banana screens typically employ two motors driving two sets of exciters with identical eccentric masses, enabling them to rotate in self-synchronized, opposite directions. At each instantaneous position, the centrifugal force components generated by the eccentric weights along the vibration direction superimpose, while components in other directions cancel each other out. This creates a single excitation force along the vibration direction. This excitation force causes the screen box to vibrate back and forth along a linear trajectory.

Product Specifications

Product Model | Screen Surface Area (m²) | Feed Particle Size (mm) | Processing Capacity (t/h) | Screen Surface Inclination Angle | Power |

1560 | 9 | <300 mm | 80-400 | 5-25 (5-stage screen surface) | 2*11 |

2560 | 15 | <300 mm | 130-650 | 2*18.5 | |

3660 | 21.6 | <300mm | 200-800 | 2*22 |

Banana Vibrating Screen

Category:

Clients

Case Studies

Certificates