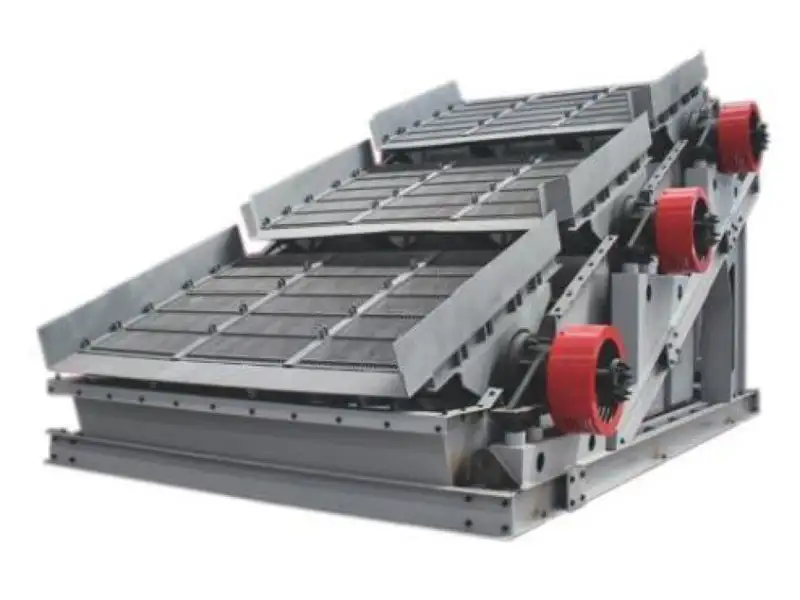

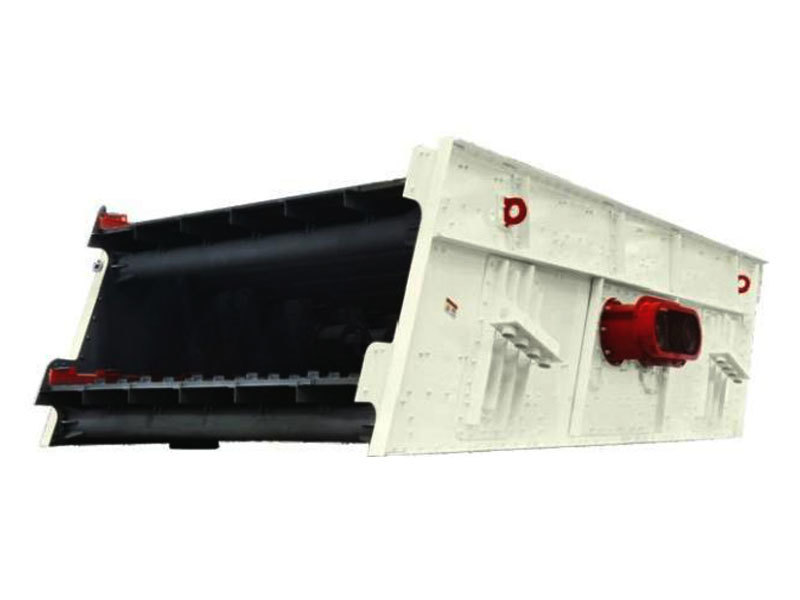

Product Description

Working Principle

Reciprocating feeder consists of frame, base plate (feed chute), transmission platform, hopper gate, roller and so on. Its transmission principle: when the motor is started, the inclined bottom plate is dragged by the flexible coupling, reducer and crank linkage mechanism to make linear reciprocating motion on the roller, and unload the coal uniformly to the transportation machinery or other screening equipment. Reciprocating feeder is equipped with hopper with regulating valve and without hopper without regulating valve in two forms. This machine is suitable for mines and coal processing plants to load coal evenly through the coal bunker to the conveyor or other screening and storage devices.

Main Features

1. Simple structure, reliable operation, easy adjustment and installation.

2. Limited torque hydraulic coupling, full load start, overload protection.

3. Light weight, small size, reliable operation, long service life, convenient maintenance.

4. The maximum feeding capacity is up to 1200 tons/hour (coal), which is the largest reciprocating feeder in China.

5. Adopting advanced planar secondary envelope ring surface mule bar reducer design, with large bearing capacity and high transmission efficiency.

6. The adjustable joints between the side liner, inclined liner and bottom plate can precisely control the size of the joints, which greatly reduces the leakage of materials.

7. The symmetrical arrangement of the driving device and the adoption of double push rods make the whole machine love force balance, smooth transmission and eliminate the torsional pendulum phenomenon when the bottom plate reciprocates.

8. The bottom plate has vertical reinforcement plate and is supported by three-way rollers, which ensures the rigidity of the bottom plate and eliminates the shortcomings of bending and deformation of the bottom plate of the current reciprocating feeder.

9. The liner plate consists of small wear-resistant steel plates, which makes it not only light and easy to replace, but also can be targeted to replace the worn liner plate according to the actual wear situation, thus rationalizing the use of materials and reducing the maintenance cost.

|

Attribute Name |

Attribute Data |

Attribute Name |

Attribute Data |

|

Place of Origin |

Xinxiang, Henan |

Mould |

Reciprocating Feeders |

|

Appliance |

Mines and Coal Processing Plants |

Core Selling Points |

Continuous Feed |

PREVIOUS:

NEXT:

Reciprocating Coal Feeders

Contact Us

Classification

Clients

Case Studies

Certificates